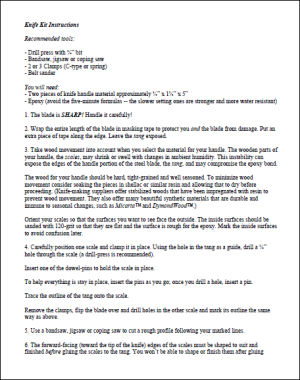

I ordered this Hock paring knife blade from Hock Tools. This third knife will have handle scales from a piece of cocobolo (Dalbergia retusa) that my brother, Tom, left me when he moved to California. For the most part, all of the steps in this process are identical to the first knife. An in-depth record of the entire knife 1 build process can be seen here. Info about knife blades is available at Hock site At the same time I worked the third knife, I was working a fourth knife, bocote, some images are shown here.

|

|

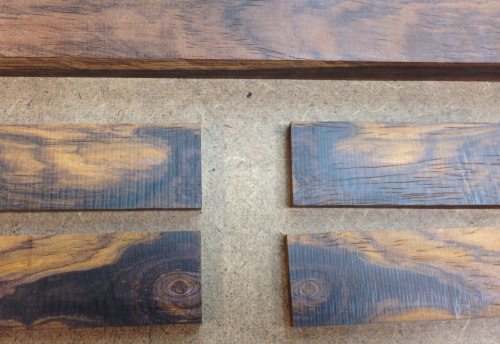

The #KP350 blade is made from high-carbon tool steel. It was forged in France and sharpened by Ron in California. |

|

|

|

This knife will have a cocobolo handle.

|

|

Wood selection: Cocobolo Dalbergia retusa Central America More info about cocobolo here. |

|

The blade was covered in tape for protection. The blade comes incredibly sharp. |

|

|

|

|

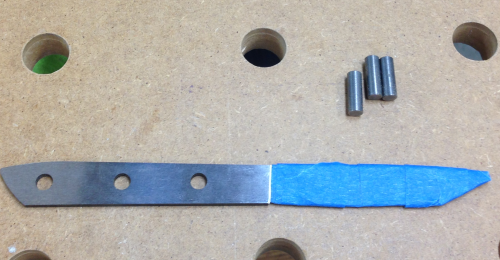

The inside surfaces of the scales and the tang of the blade were sanded to 150x to provide a better adhesion surface. Then the mating surfaces and the pins were cleaned with acetone. |

|

I chose a strong, water-resitant epoxy adhesive, Devcon 2 Ton® Epoxy...comes in two 4.5 oz. bottles. |

|

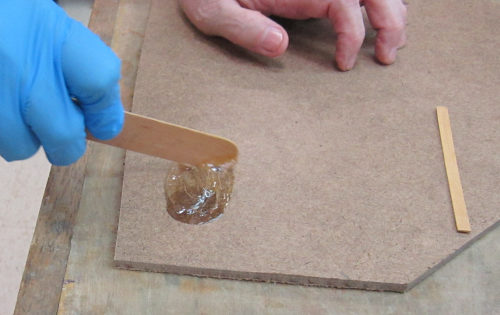

To mix...equal dollops of the resin and the hardener were squeezed out. |

|

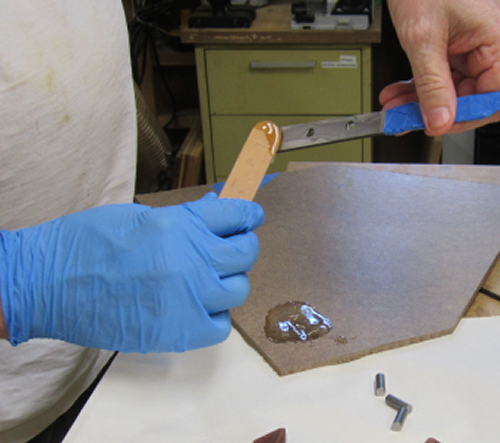

then mixed... |

|

The adhesive was then spread on to one side of the tang...then the knife tang and scales are clamped overnight. |

|

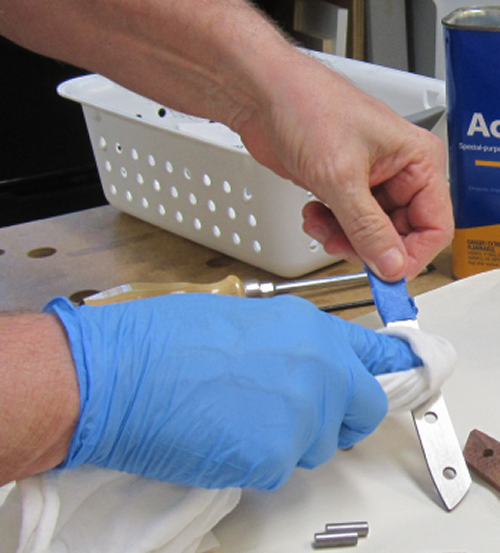

After glue up, the first shaping phase of the grinding of the wood and the metal was done on a belt sander with 80x paper. The cocobolo dust is fairly caustic so I ran both shop air filter systems and wore a protective mask. I washed off exposed skin after the sanding process. Secondary grinding of the pins was done on a 1 x 30 belt sander with 80x. |

|

Further removal of metal and wood was done with the Rotex 90 sander with 40x paper. After all the metal and wood was taken down to proper size, the grits were progressed on the Rotex 90 from 40x-80x-120x-220x-320x-400x. |

|

The finishing cycle consisted of multiple coats of Waterlox® wiping varnish. Each coat was saturated and then dried using wet/dry sandpaper. Two saturations and rub-ins were done at each grit from 400x-600x-800x and then single saturations at 1000x and 1500x. Then a few coats of Tru-Oil®.

|

|

|

|