A future project (a cherry Shaker style side table) will have tapered legs...so I decided to build a jig to improve my ability to taper on the table saw. I have an old metal taper jig that I never really cared for...and I wanted some extra safety.

|

|

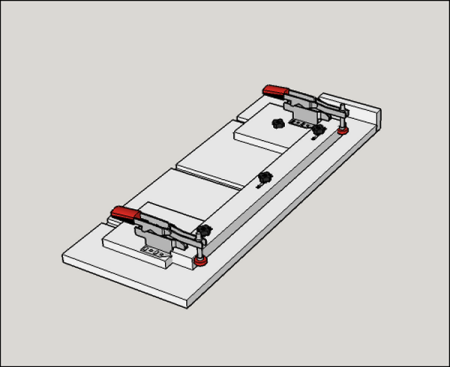

Here is my Sketchup design of the taper jig. The materials will all be wood or jig parts left around the shop.

|

|

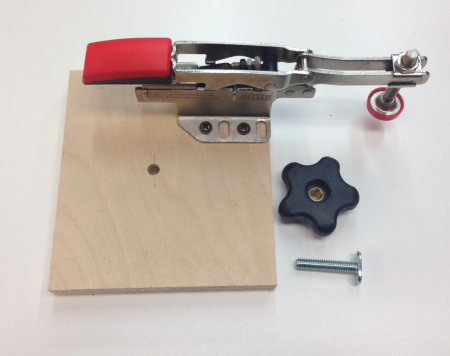

My inspiration for this design was the fact that I had a couple of Bessey toggle clamps that I wanted to put to use and I had read a very good article online that included the jig shown to the right. www.woodworkersjournal.com/five-practical-ways-to-use-toggle-clamps/ |

|

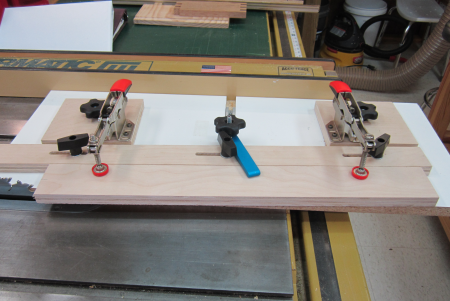

| The sled will be a 11 1/4 wide by 30 inch piece of melamine particle board. The two clamps are screwed to 3/4 Baltic birch plywood...the hole will accomodate the 5/16-18 T-bolt that will thread into a 5 star knob.

|

|

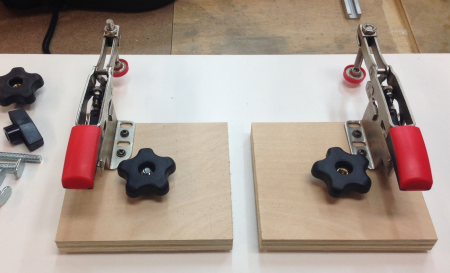

The two clamp assemblies... |

|

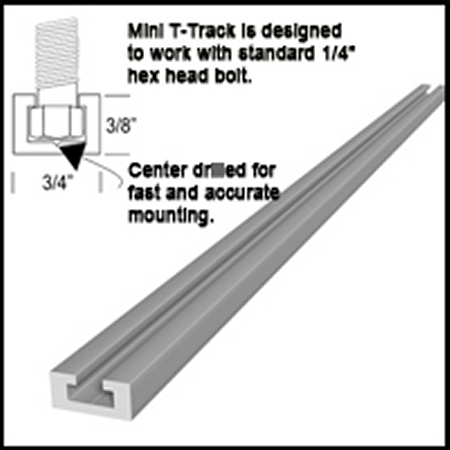

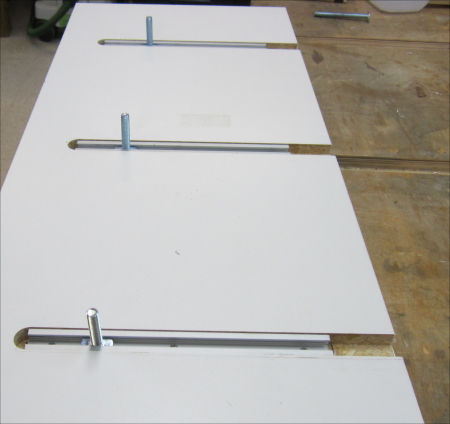

I cut a 24 inch run of mini track down to three pieces @ 8 inches.

|

|

The mini-track is 3/4 wide and 3/8 inch deep. It is designed to handle the flat head of a 5/16-18 T-bolt or the full bolt head of a 1/4-20 bolt. |

|

I will be using 5/16 flat head T-bolts because I had a number of turn knobs in the 5/16-18 thread. |

|

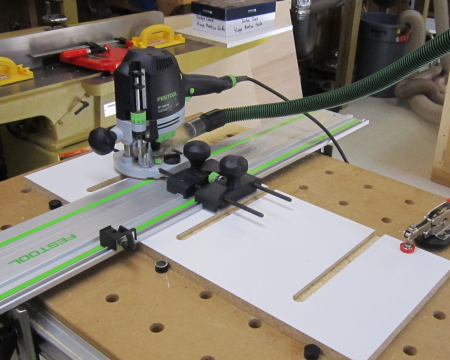

The three grooves were with made with the router on MFT3 table. |

|

I used contact cement to secure the t-tracks into the slots. Here I mounted some screws into scrap wood and slid the tracks onto them while I put on the cement.

|

|

Since the aluminum t-tracks were cemented to strand board, I was concerned that the stress on the tracks during clamping would be too much to hold...so I put some small pan head #4 x 3/8 inch screws that were small enough that the bolts could pass over them. |

|

All three tracks installed and bolts put in... |

|

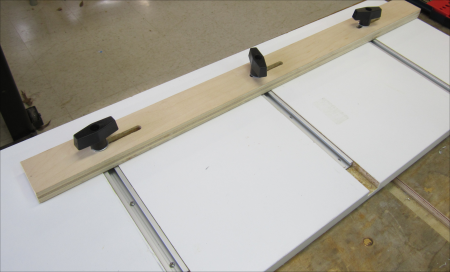

I put slots in the taper alignment board to allow for easy angle adjustments... I used T handles with extra washers. |

|

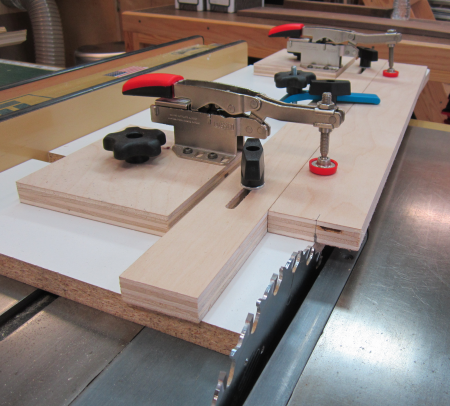

Here the jig gets a test fit...the sled goes against the fence...the taper angle is set with the angle alignment board and the piece to be milled is secured with the Bessey toggle clamps and/or other hold downs... |

|

The front edge mark is set at the blade and rear edge is set on the edge of the sled. This allows for a safe taper cutting and easily repeatable tapers for the legs on my upcoming project.

|

|

The rear stop is made of oak cut from an old chair leg. The cuts were made with a tenon saw. |

|

|

|