|

Looking to make some

staked furniture...sawbench, stools and chairs etc... with

legs that involve tapered tenons and tapered mortises.

After some skill building, the first project will be a staked sawbench with a future eye to a staked chair. The designs are based on the readings and plans from The Anarchist's Design Book by Christopher Schwarz. |

||

|

The tapered mortises will be made with a pilot hole (minimum of 7/16 inch) drilled on the Nova drill press...angled using the shop built drill press table angle jig. |

|

|

| The pilot hole may also be made

with hand brace and augers...I plan to try the hand cut pilot

holes... I have 1/2" and 5/8" Wood Owl 7.5 inch Ultra Smooth Tri-Cut augers on order. |

|

|

|

Then a hand bored tapered hole

will be made using the pilot hole as a guide.

The taper tool will be the Veritas

Pro Taper Reamer.

|

|

|

|

Manual

for the reamer.

|

||

| The reamer is

set at 12.8° and is the complement of the Veritas Tapered Tenon Cutters |

|

|

| Manual for the tenon cutters. | ||

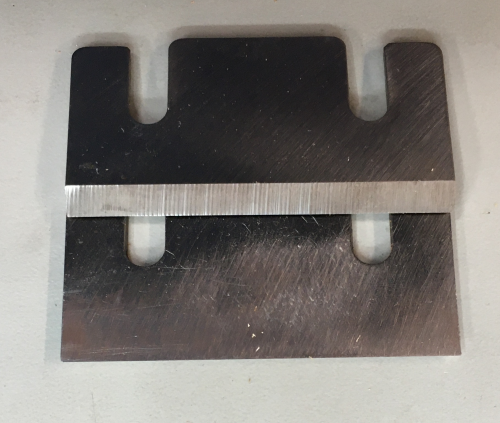

| OEM picture of one of the cutter blades... |  |

|

| Sharpening the tenon cutters. According to Manual... The high-carbon steel blade is supplied with a 30° bevel. As supplied, the cutting edge is adequate for rough work in most woods; however, accuracy and surface finish will be improved with additional sharpening. Start by lapping the back of the blade and then proceed to honing the bevel. A 1° to 2° micro-bevel honed on the final edge will strengthen the edge and reduce your sharpening time. |

The backs were no where near

flat...image shows two OEM blades.

The 30° bevel was quite striated...the work honing had been rough...  |

|

| This is the striated bevel... |

|

|

| This is the honed bevel... |  |

|

| Christopher Schwarz

article at Popular Woodworking... "Chair Joinery: Tapered Tenons and Tapered Mortises" Includes a short video that is available on YouTube |

|

|

| Video: "Using

the 5/8" Veritas tapered tenon cutter" on YouTube. More info and videos at the site, Windsor Workshop. |

|

|

|

From the master chair maker,

Peter Galbert, "Tapered Mortise and Tenon"

A PDF from the American Association of Woodturners. |

||

| Purchased the Popular

Woodworking video... "No-Fear Chairmaking: by Christopher Schwarz |

|

|

| Video of Schwarz on The Woodwright's Shop discussing staked furniture. |  |

|

| Video of Brendan Gaffney of Popular Woodworking discussing the Schwarz staked chairs |  |

|

|

Shannon Rogers has multiple

videos on the building of a "Perch Stool".

I do not see me making one but the five videos are very informative. Videos listed here. |

|

|

|

Practical

Exercises: At 90°

Drilling

and Reaming Mortises

Tapering

Tenons

|

||

First use of tools: Used Veritas taper cutter 5/8" on an oak 1-inch dowel... |

|

|

| First tapered tenon... |

|

|

| I drilled a through 1/2 inch

pilot hole with a brad bit on the Nova DP...into a 1.75 inch

thick CTD slab of maple. Then ran the Veritas 5/8 inch pro taper reamer into the pilot hole using a hand brace. This was all at 90 degrees. |

|

|

| Rough finished tapered tenon and

tapered mortise... |

|

|

| Tapered tenon in tapered mortise... |  |

|

| After reading up on adjustments, etc. I re-tapered the

tenon with a 1/2' unit with a sharpened blade. I started the taper holding the unit and twirling the cutter like sharpening a pencil. Much better cutting action with sharpened blade. |

|

|

| Then I placed the cutter in a vise and tried it that way...worked well |  |

|

| The tapered tenon... |  |

|

| Friction fit was so tight that it held the block easily |  |

|

| At the skinny end...the show end the 1/2" hole-tenon connection left a gap... |  |

|

| Checked for square...pretty close in left-right plane... ...but it was off by about 5° in near-far plane. |

|

|

| Tried again with a new 1/2" drilled pilot hole and reamed a

new conical hole...trying to pay careful attention to square in

the world, but... ...gap still there, off square still there, re-tapered the tenon...still there. |

|

|