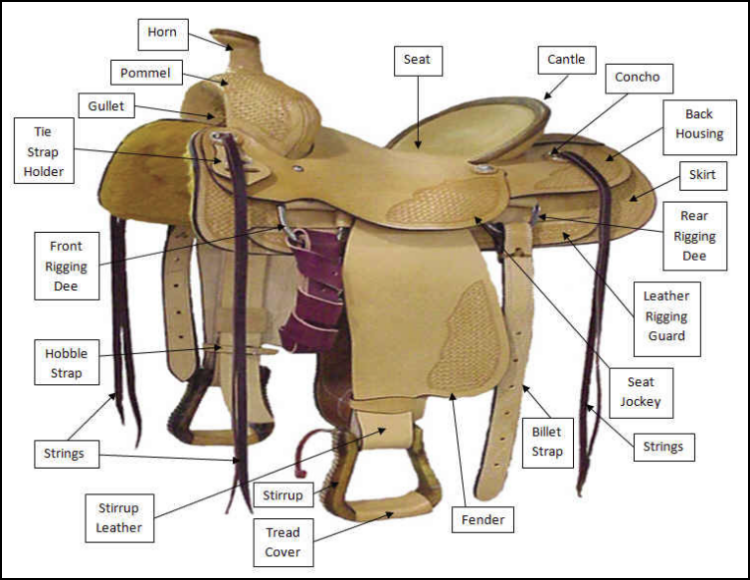

Saddle Repair Asa received a used, gifted saddle. The leather needed conditioning and there was a missing rigging dee. A new leather loop needed to be made to hold the new dee. Term Identification...

|

|

Leather

Conditioning |

|

Asa cleaned the leather well...she then put on multiple coats of neatsfoot compound. She applied, on key leather locations, several coats of my boot care rub. |

|

The reconditioned leather. Asa did a great job. |

|

Rigging

D Replacement |

|

The torn leather loop was attached to the saddle tree...this base was a synthetic material.

|

|

The leather loop pad had been secured with four 1 inch fine thread screws. There were also numerous staples...~3/8 inch gate x 7/8 inch legs.

|

|

Additionally, from the outer part of the saddle, near the horn on the pommel, there was a screw with a grommet. This screw went through the leather seat, through the loop pad and into the tree. |

|

There was also a screw setup as above except that it went through a concho near the pommel. |

|

This is the torn rigging loop along with the leather replacement we cut out. Our leather was not as thick as the original but it should perform reasonably well. |

|

The lineup...pretty close...our remnant was slightly short in a couple of corners...no problem. |

|

A new rigging dee was secured from the internet. We got it a little oversized, made the mistake of measuring the old ring on the outer edges...should have been ordered by interior measurements. We put in a single snap rivet to hold the material and then attempted to put in two more. The conditioners really darkened the leather. |

|

The angle of the leather loop made the second and third snap rivets not work well...so we put in a couple of stouter, copper rivets. The new loop was secured to the tree with 1/4 inch gate x 7/8 inch leg, 18 gauge crown staples fired by pneumatic crown stapler...also four screws. Finished product. |

|

Aimee, Asa and I did the repairs on their carport during the 2020 pandemic lockdown...we observed masking protocols. |

|