|

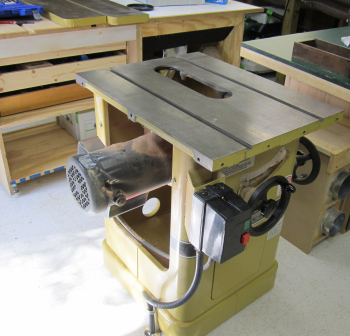

The Powermatic 66 is the central focus of the shop. It has a shop built outfeed and downdraft table attached to the rear of the unit. Dust collection and storage have been built into the area to the right side of the saw under the extension table. This table has been in service for 12 years without an overhaul. The blade elevation and blade angle adjustment mechanisms had gottem very difficult to use. It was time for an overhaul and tune-up. |

|

Phase 1 was to clean and lubricate the bottom section of the P66.

|

|

|

In particular, the best tip from the

article was to use a LPS F104° solvent degreaser

|

|

|

and the LPS Force 842° Dry Moly

Lubricant.

|

|

|

First we pulled away the outfeed and downdraft table/cabinet assembly.

|

|

|

Then pulled the front and back rails

to remove the fence assembly bar.

|

|

|

After separating the right cabinet

assembly and extension table, we pulled the cast iron side

table.

|

|

|

With both side table removed we were

ready to take off the main table.

|

|

|

This exposed the heavy build up of old

paint, resins, saw dust etc. that was causing our problems.

|

|

|

We began a methodical clean up that

involved multiple vacuum passes.

|

|

|

This process really paid some huge dividends.

|

|

|

We used the Festool C22 dust

collection with the Oneida Dust Deputy cyclonic addon.

We added Stinger miniature dust collection attachments that really got into small places with incredible suction. |

|

|

We suddenly got to the point where we

realized that we had cleaned all the places that the overhaul

instructions had said to clean...all that was left were places

where they said to spray in a penetrating lubricant. So we started by removing the motor. It is a powerful and heavy Baldor unit. |

|

|

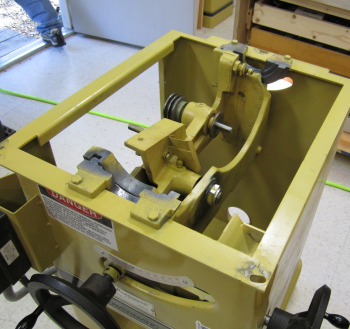

Next came the trunion assembly.

|

|

|

Now we were pretty much down to the

cabinet shell.

|

|

|

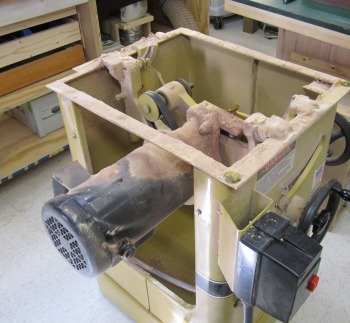

It was a magnificent day...we pulled

the internal assemblies outside so we could used compressed

air and wire wheels for the final clean up stage without

getting dust in the air in the shop.

|

|

|

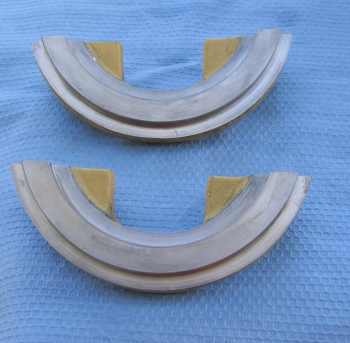

Here are the rear and front trunnion pieces. Wire wheel cleanup got them quite clean. |

|

|

Hear are the trunnions with the LPS

spray on them. We really liked this quick dry lube.

|

|

|

We were able to disassemble and really clean the worm drive raising shaft and tilting shaft. The biggest mystery of the overhaul was that the two

shafts each had a Woodruff key that seemed to serve no

purpose at all. |

|

|

The hardest step in the entire process

was breaking down the nut on the pivot shaft. This was a

"self-locking" nut that was 1 5/8 inches.

We had to dig out my 3/4 inch drive SAE socket set and use the BFH gentle persuader to pound the unit for a bit. |

|

|

It finally came off and now we had disassembled everything that could be pulled apart.

After a major cleaning and thorough lube job we started putting it all back together. |

|

|

Here is the trunnion unit back in with all turning wheels reinstalled. Both the blade height system and the blade angle system move smoother than they did the day I bought the unit. This is a major improvement. |

|

|

This ends Phase One. The lower unit is overhauled.

|

|

|

The first step of Phase Two was to refinish the cast iron table. We started with a wire wheel to remove bad spots or rust. |

|

|

Then we moved throught varying grits up to 400 on variable orbit sanders. Then some manual work with wet sanding up to 2000 grit to really get the center section smooth. |

|

|

Every nut and bolt was wire wheeled

and coated with camelia oil.

|

|

|

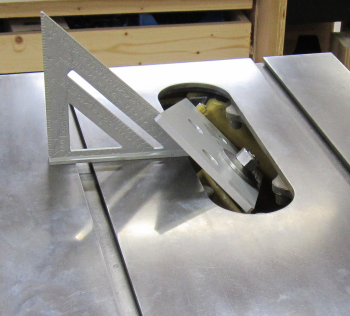

Once the table top was waxed we placed

the unit back on the saw. Then we began the tweak to make the

surface level and square to the saw arbor.

|

|

|

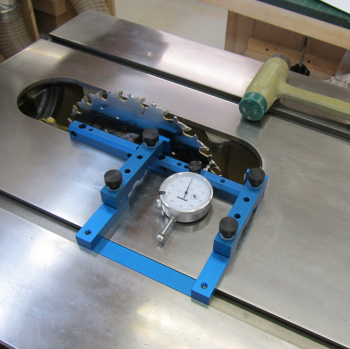

We use the A-Line-It® guage in the mitre groove to get blade run measurement to make the table top square. We used a MasterPlate® rather than a blade to make sure there was a minimum of deflection. After many a tap with the dead blow hammer we finally got a runout that was within .001 inch. |

|

|

Measuring runout at a 45° setting

enabled us to determine the front to back leveling of the

tabletop.

We again reached a tolerance of .001 inch. |

|

|

Blade angle at 90° was achieved and

the scale was calibrated. We decided to not "stop" the device

at 90°.The adjustment will actually carry the arbor to a

greater degree. Rather than counting on the accuracy of the

stop, we will calibrate it precisely when starting a new

series of cuts.

|

|

|

Verification or 45° runout to a blade.

|

|

|

Final verification of 90° runout to blade. |

|

|

Placing and leveling of the two cast iron wings was as difficult as any adjustment. The act of the final bolt tightening always changed the level of the wing. After many an attempt we finally got happy with the entire surface. We replaced the front and back rails for the fence assembly. |

|

|

The original 2000 install of the extension table had been frustrating because the holes in the table had not matched up well with the holes in the front and rear rail assemblies. We decided to make this right so we drilled a proper set of holes and replaced all of the hardware. After the fence was reinstalled we calibrated and adjusted the fence runout. |

|

|

The overhaul is complete. All is clean, lubed,

calibrated and adjusted within fairly close margins. Most

experts said that error of .002 inches was acceptable and we

met .001 in every instance. I have not had to set the locking features on the

elevation or angle shafts for years because they were so

difficult to move. |

|

|

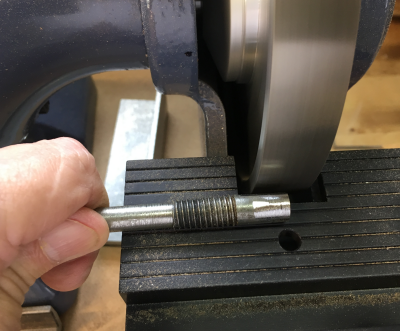

Locking the table became more and more

difficult because the locking handle on the wheels became

stripped...to fix I took the shaft and ground off the threads,

|

|

|

...added a flat spot and reinserted

the 3/32 hex to grab the flat.

|

|

|

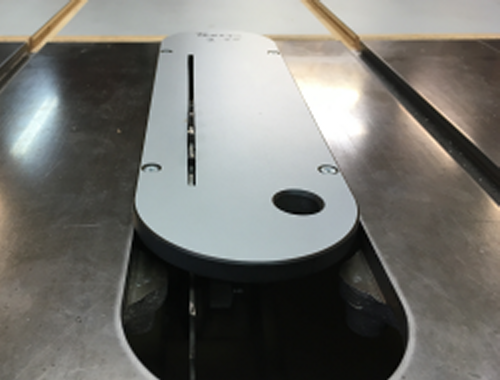

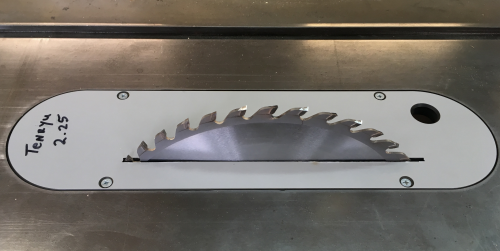

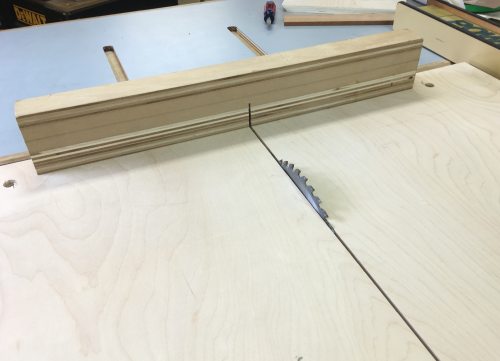

While working on a project, I tilted the P66 blade to 45°...when I returned to blade to 90° I prepared to put the zero clearance insert back over the Tenryu blade. It would not fit down over the blade...the blade appeared to have moved toward the arbor about a half of a kerf....this is a thin blade, .111inch. In this image the insert is over the blade and you can see that it is touching the left side of the table insert cutout. |

|

|

My first thought was that the insert

had warped? but it is phenolic...quite doubtful...since I

needed to use the crosscut sled anyway...I put it on the saw

and tried to raise the blade...it was off in the same manner.

|

|

|

I put in the OEM P66 insert...it has a

very wide gap...blade was clearly moved to left rather than in

the center...

|

|

|

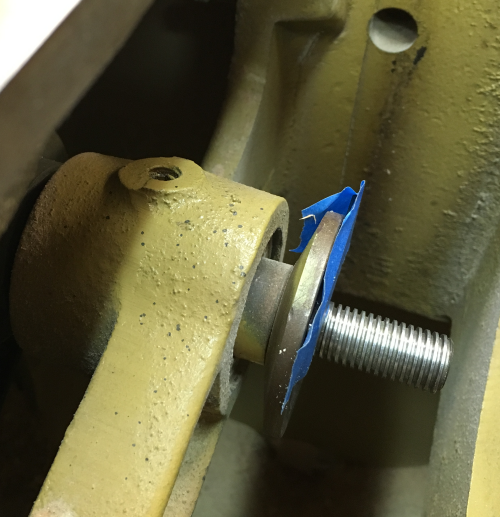

After verifying that the blade was properly parallel to shaft...and wracking my brain for possible solutions...the only thing that I could think of was that while tilted to the left, the weight of the Baldor motor, trunnion assembly, etc. had somehow moved the arbor shaft. This view is from the rear of the P66...this shows the housing in the cast iron which has a hex head set screw that holds the arbor shaft in place... |

|

|

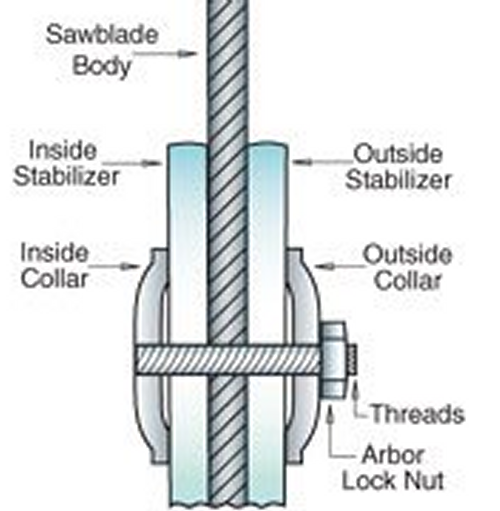

The set screw was not loose, but it was not "shut down tight"...it was possible that this screw had vibrated loose enough to allow movement... moving the shaft out did not seem possible...in an attempt to determine how much to the right the blade would have to be I gathered up all of the shims from a Freud dado set and placed them on the 5/8 inch shaft...it was about correct...ended up being about .0550 inch |

|

|

My first thought was to secure set of blade stabilizers to see if the offset would be bearable. The thinnest I could find were 3/32 or .098 inch...the pair are made by Amana...STF-4 with 4 inch diameter x 5/8 inch bore. |

|

|

I think that this will be too much spacing between the inside collar and the blade...it will make the blade be too far to the right...but I will give it a try.

|

|

|

As a test, I took a 3/32 setup

block...

|

|

|

...and taped it to the shaft

collar...the test was an approximation at best and the fit

showed that it might be close on the right edge of the slot in

the cross cut sled.

|

|

|

|

|

|

Because I really needed the P66 up and

running and I really wanted to work with the crosscut sled...I

decided to attempt to move the shaft from the motor housing

area...I pulled the motor cover and found easy access to the

end of the arbor shaft.

|

|

|

I brought out the right tools...a

long, heavy wooden chunk of yellow pine...some gloves and a

"gentle persuader"...a lump hammer.

|

|

|

After loosening the arbor shaft screw,

I put a subdued but firm whap on the shaft and felt a nice

nudge. Two lighter ones and it seemed about right...

|

|

|

Back in position...the Tenryu zero

clearance is the test...

|

|

|

Even more important...the location in

the kerf of the cross cut sled is dead on...tightened the lock

screw on the arbor shaft.

|

|

| After

various attempts to fix the ability to lock the height of the

blade...it was decided to tear down the P66 a second time to

assess the Woodruff Key. The issue is that the the blade height adjustment was insufficiently locking which meant that the depth of a dado would not remain constant. The torque at motor start up was causing the blade height to drop. |

|

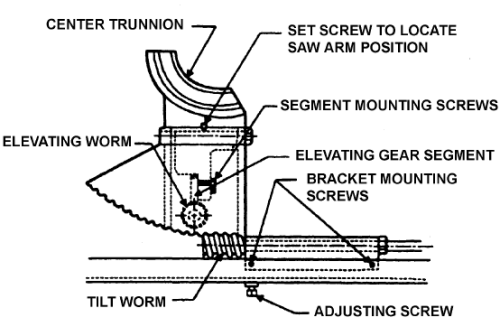

| There are two shafts that have

Woodruff Key locking mechanisms...these two shafts when turned

engage, activate and then lock the elevating worm and the tilt

worm. |

|

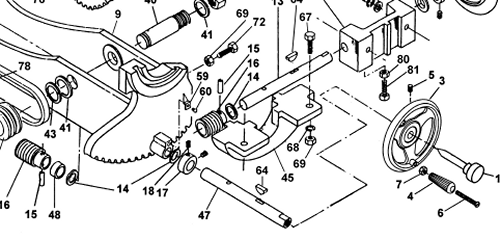

| Of major concern at this

time...the raising shaft on the front, number 47 in image with

the Woodruff key #64...when the shaft locking pin was reaching

its greatest extension into the shaft it was not causing the

Woodruff key to engage the housing with enough pressure to lock

the raising shaft. |

|

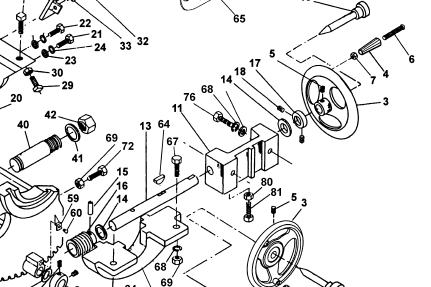

| Additionally we will also

check the tilting shaft on the right side of the machine, number 13 in image with the Woodruff key #64 |

|

| When this problem

began we had tried a series of fixes without joy...we then projected that the issue was that the Woodruff key was not securing the worm gear...possible reasons were due to damage of the key, damage to the shaft locking pin, misalignment of the housing of the shaft collar #77, or other unknowns. This image is the shaft locking pin...pic from eBay...often the point becomes deformed...I have filed a few back... |

|

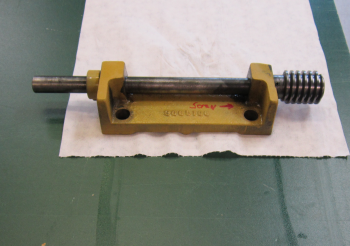

| Shaft locking pins had also caused grief when the handle would rotate on the pin and it would tighten...see Handle Fix above...shown in image is one of the shaft locking pins and a Woodruff key |  |

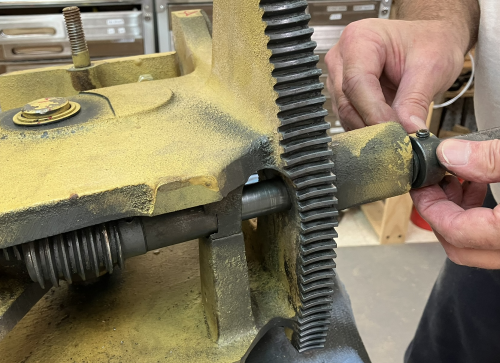

| Image shows the bottom side of the front raising shaft...hands on the shaft collar #17...it was loose...the two set screws are hex 5/32 |  |

| Here the front raising shaft is

removed from the trunion...pen shows where Woodruff key rides in

the half moon keyway in the shaft. The worn flat on the near end is engaged by the handwheel which turns the shaft...the far end of the shaft has s the worm drive which engages the trundle and raises the blade. |

|

| We cleaned all surfaces well and

lubed...when putting the raising shafts and tilt shaft back into

position we were careful to examine wear and tear etc. On the tilt shat we reversed the key...to expose the clean side to the shaft locking pin... On the raising shaft the Woodruff key had already been reversed...we did that at the first big overhaul. Image shows the worn surface alongside a replacement Woodruff key. |

|

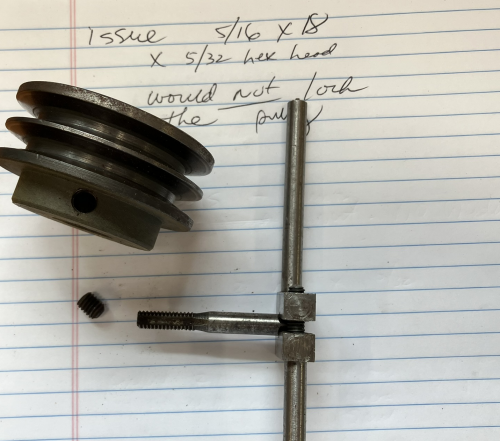

| Though not a part of the original

problem, the pulley on the trundle was loose when we took it

off. |

|

| It was determined that the

threaded hole for the 5/32 hex screw did not allow the screw to

adequately engage the shaft. |

|

| Tapped the 5/16-18 shaft. |

|

| So...we replaced or readjusted

the Woodruff keys...repaired any surface we could...make sure

that all adjustment points were properly aligned and tightened. After preliminary tests indicated that shaft was more secure...we put the P66 back together and then tested... |

|