|

Although I have no plans to

turn a lot of pieces, I bought a small Rikon 70-100 Mini

Lathe.

|

|

|

When stored...it is placed on a low trolley with

casters and rolled into the southwest

corner. |

|

| A picture of the current trolley. |  |

| Bottom of the trolley...2 inch

casters. Two fixed, two variable, none with brakes. |

|

|

This small lathe has 12? Swing and 16?

between centers.

When in use, it is typically clamped to the

table saw outfeed table.

Here is is being used to shape conical ends

for making conical tenons on the legs of staked benches.

The lathe does not have enough room between

centers to create the legs we need.

|

|

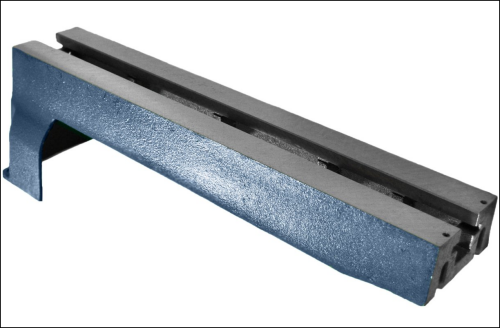

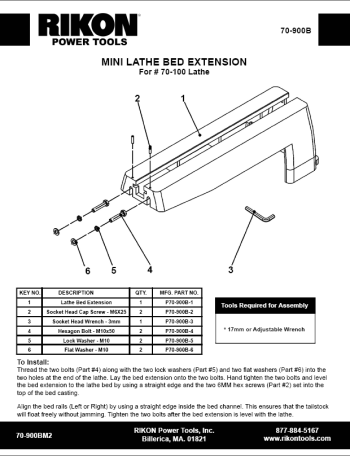

| Secured a Rikon 24 inch cast iron extension, 70-900B. |  |

| Installation instructions...Rikon

OEM PDF |

|

|

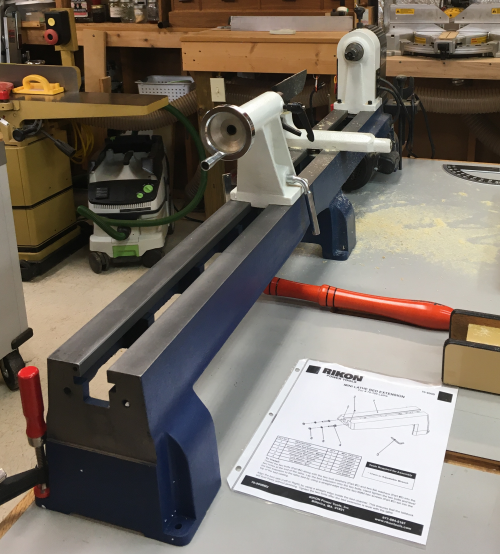

Extension installed.

|

|

| Bed is now close to 5 feet

long. This will require either a tear down of the extension or the creation of a longer trolley... |

|

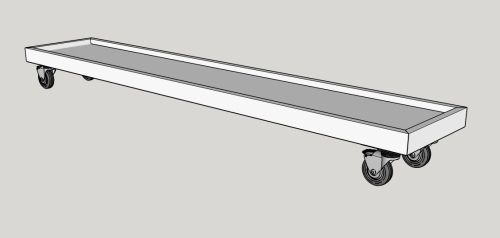

| Cindy and I did a CTD trolley and

decided that it could be navigated and stored properly. New trolley will accommodate the full bed. Sketchup... |

|

| It will have same size, 2",

casters... but they will all be variable 360° and they will all have brakes. |

|

| After looking at the wood supply

in the attic, I realized just how the pandemic stopped me from

buying wood. So...recycling the first trolley became critical...re-calibrated the frame For the frames I milled, jointed, ripped at bandsaw, surfaced planed 1.25 x 1.5 strips out of some 2 x 10 pine that was pretty dry and only mildly wonkie. All securing was with screws, #8 1.5 SH red drive. |

|

| Made some strip plates to better secure corners and material to support bed and allow for screws to hold down the casters. |  |

| Put in a support where the bed of the original trolley ended...seam of the two bed plates will rest on this support. |  |

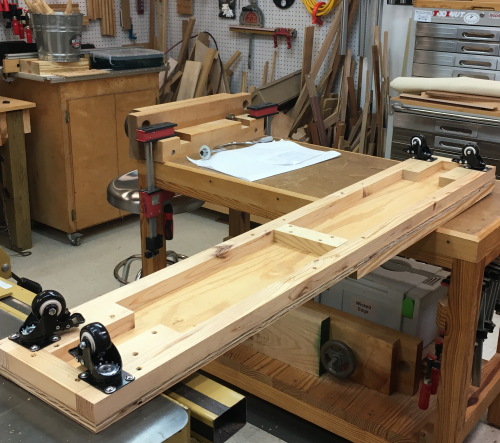

| Frame ready for the new bed

plate... |

|

|

Add on bed attached...all

casters in...

|

|

| CTD fit in the corner...navigation is slow but easy. |  |

| Rails installed...lathe in

storage. |

|