Tenon Taper

Cutter, Holding Jig

|

|

|

Using the taper cutter with it in your hand

is not ideal.

|

|

|

It was way easier to mount the cutter

in a vise and take the work piece to the cutter.

However, tightening the vise faces

around the uneven and tapered cutter was sometimes difficult.

|

|

|

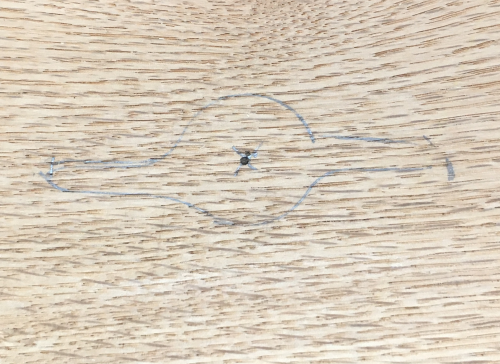

Designed a jig to hold the cutter easily in a

vise. The two cutters that have are 5/8 and 1/2. However, the physical casting and the external measurements of the two cutters are the same. Put the cutter on the oak blank and traced out the

form. |

|

|

Circular face on the cutters was .95"...with two

wings that were off set. |

|

|

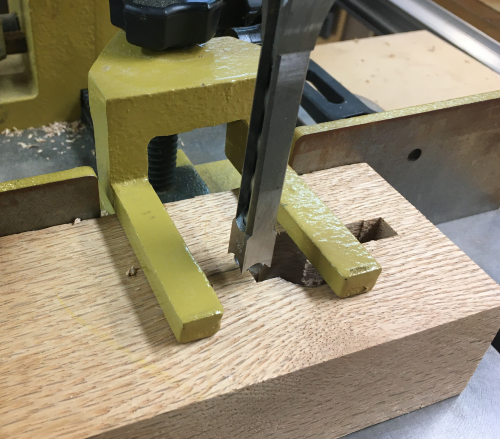

The holes were bored with FAMAG Bormax 2.0 bit, the 1

inch unit. RPM oak = 500, well secured |

|

| The trenches for the wings were mortised. |

|

| Second dry fit

determined where trenches had to be wider to accommodate blade

and screws. |

|

| Then the hole was tapered using

the reamer in a hand brace. |

|

| Final fit was

satisfactory...tight enough but no binding. |

|

| Jig in use. |

|