I ordered this Hock carving knife blade from Hock Tools.

It is model CKSB125, a one and 1/4inch stab knife blade made from high carbon steel and hardend to Rc62. This carving knife will be used in my shop. It will have handle scales from a piece of cocobolo (Dalbergia retusa) that my brother, Tom, left me when he moved to California. For the most part, all of the steps in this process are identical to the knife build #5, a carving knife. Details of that #5 build are shown in greater detail here. Info about knife blades is available at Hock site

|

|

The handle for this stab knife will be thick and stocky. I drilled the holes for the pins, dropped pins in the holes to keep the scales aligned...then shaped the blank at the scroll saw. |

|

The rebate was created by placing the scale blank in a pattern maker's vise, marking the outline with a blade and using a hand router to remove the bulk of the material...

|

|

...then paring chisels were used to clean it up. |

|

A blade fit... |

|

The roughed out scales are ready for the epoxy. |

|

Epoxied and clamped with four Bessys... |

|

| Out of clamps...ready to begin shaping... |  |

...first round of sanding and shaping done with 80x on belt sander... |

|

...smoothed out to the rough shape... |

|

After the desired shape was acheived, further removal of wood was done with the Rotex 90 sander...the grits were progressed from 60x-80x-120x-220x-320x. |

|

The finishing cycle consisted of multiple coats of Waterlox© wiping varnish. Each coat was saturated and then dried using wet/dry sandpaper. Two saturations and rub-ins were done at each grit from 400x-600x-800x. |

|

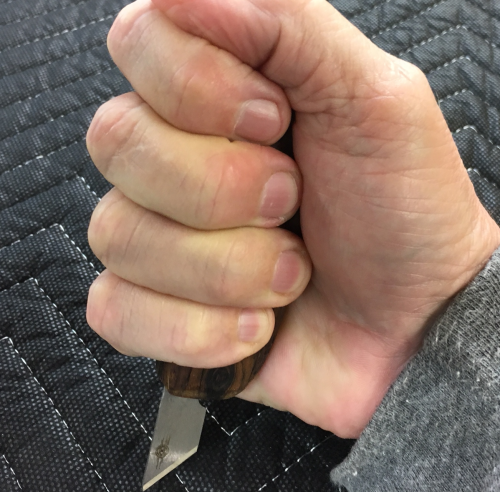

The spine of the blade was left in the wood to make the wooden handle grip better in my fist. |

|

The stab knife in the fist... |

|

|

The finish was smooth.

|

|