During the continuous reassessment and reconfiguring "Kaizen Overhaul" process in the shop, I have created numerous new tool storage locations. As I have moved some tools into drawers rather than hanging on the walls I decided that I needed to custom fit sharp edge tools so that they would not roll around and lose those well sharpened edges. I considered French fitting these objects but the time taken to do this was just too much...so I switched my focus to foam and found Kaizen Foam.

|

|

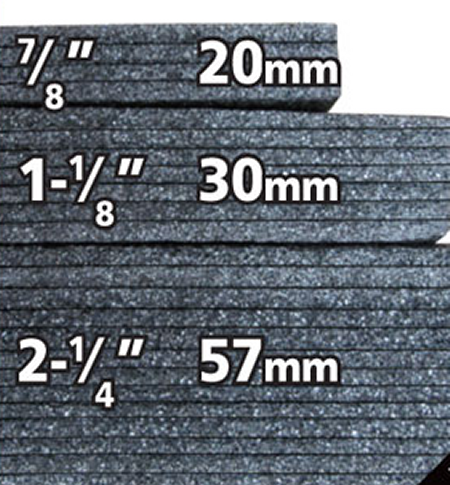

Kaizen foam comes in sheets of laminations of 1/8 inch layers. I wanted to use this product in somewhat shallow drawers so I purchased the thinnest option, the 7/8 inch version. The theory is that you cut away and remove several layers of the foam to make the hole for the tool. |

|

Quick video overview of this FastCap product. |

|

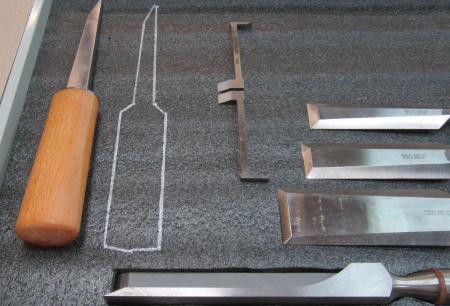

I started with a drawer that will hold specialty chisels that I do not reach for very often. In this image I have drawn the outline of a large mortise chisel by Ray Iles. Very clunky handle, massive structure. You can see other laid out tools for visuals. The large Sorby corner chisel at the front of the drawer is already secured in its custom cutout. |

|

The foam is that cut with an exacto blade and the foam is pulled away. The layer separation process was not nearly as clean as the video online. The layers are not so vividly defined. It was not bad for an early attempt. I hope to get better. |

|

The fit was decent...after removing some more material at the handle end the chisel sat very securely.

|

|

This process will continue until the drawer is totally laid out. The major benefit of tools not moving, not damaging edges is a wonderful thing. But perhaps even better is a place for everything and everything in its place. It is very easy to see what you are missing. |

|

Finished drawer liner for drawbore pins and specialty chisels. |

|

Rasps and rifflers... |

|

Squares, dovetail markers, and marking gauges... |

|