Lathe Tool

Storage

|

|

|

Using the lathe more often...added an extension...this really increased the footprint of the lathe on the P66 outfeed table. In particular, I found I was having issues getting

lathe tools and measurement tools into safe places. |

|

|

This quick project was a holder for

the three Easy Wood turning tools that I use...I shortened

the tubes that came with my tools...I played with size

of hole and spacing...the tubes were 2 inch OD.

|

|

|

Burned up some shop cut-offs...used an old thick slab

of cherry, oddly shaped ...jointed an

edge...then cut at bandsaw to rough square... |

|

|

planed to square... |

|

|

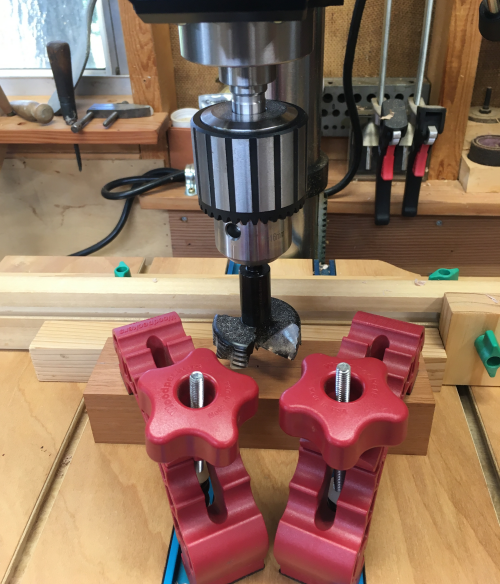

The holes were bored with FAMAG Bormax 2.0 bit, the largest one in my set (2 1/8"). Big bit, but running at the right speed and work piece was well held...did great in both the stopped holes in cherry and the through holes in oak. RPM oak = 250; cherry = 330 |

|

|

The lower cherry block and upper

oak block were secured to a piece of yellow

pine.

Shortened tubes freely float in the

rack, no adhesive in holes.

|

|

| Kaizen foam pieces were put in the bottom of the tube to protect the carbide cutters. |  |

| A piece of Crubber was put in the

v-parting tool tube to protect the Kaizen foam. |

|

| Chamfered edges...either at

router table or plane. |

|

| Then I played around with storage

ideas for a few measurement tools...calipers, square and

rule...laid them out with Kaizen foam... |

|

| Made the French fit cut outs and

added some trim to hold the foam in place. |

|

| Finished project. |

|