|

The finished product.

|

|

|

Base Build

|

|

|

The Garden Shed is located to the west of the shop. The shed will measure 8 x 10 of interior space with a covered area in the rear. The exterior is identical to the shop in terms of materials and design. The base of the shed has 2 x 8 treated rim joists. The joists are supported by 4 x 4 posts on floating piers. |

|

|

Floor joists are treated 2 x 6,

secured with joist hangers.

|

|

|

The floor Joists are on 16 inch

centers with floating pier supports.

Electrical circuits to the front of the shed were pre-strung and secured to the rim joists prior to the flooring being installed. |

|

|

Shed decking is 3/4 treated plywood.

Secured with Liquid Nails adhesive and screws.

|

|

|

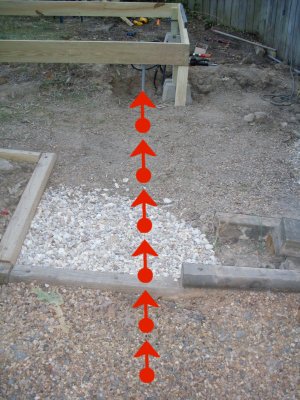

Electrical supply for shed was 6 guage

3/1 service wire connected to the shop power panel box via a

40 A 220v breaker.

The wire dropped inside a PVC conduit. The conduit was buried undeneath the gravel walk way. |

|

|

The conduit goes under the French

drain pipe (hidden in the walkway) and then under the

landscaping timber.

|

|

|

The conduit comes up in the northeast

corner. The ground wire and all pre-strung electrical wiring

converged in this corner.

|

|

|

James and George on the decked base.

|

|