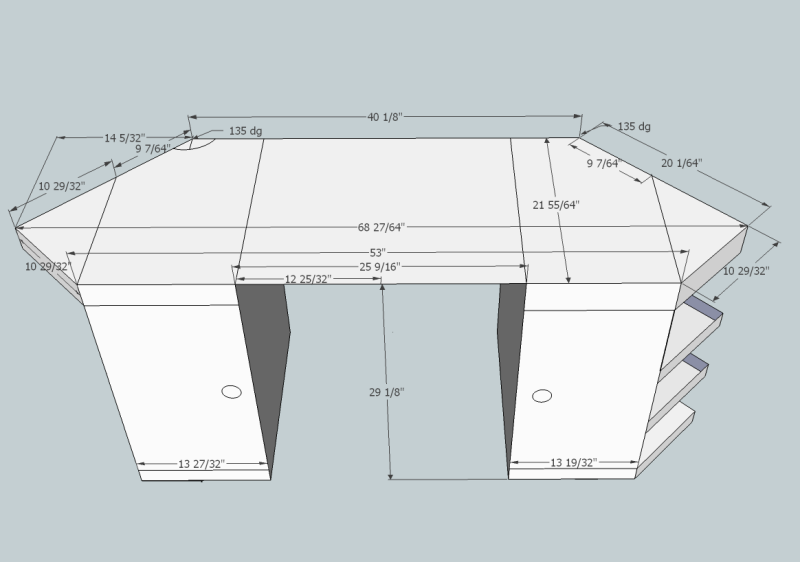

A friend, Boba, wanted to build a desk for his daughter Emma. The spot for the desk was a corner that was not a 90°...the wall had 135 ° angles. Boba created a Sketchup drawing to get us started.

|

|

It was decided that the desk would be painted and the wood choice was Baltic birch plywood with poplar edge trim. After downsizing the panel goods in the garage, the wood was moved to the shop. Here the top is cut on the somewhat odd angles using the Festool T55 track saw on the MFT3 table. |

|

| The top was then used to accurately layout the two carcase boxes. |

|

After cutting all of the panels for the carcase, Boba sanded and then primed and painted the panels. |

|

The front trim for the top was 3/4 x 1 inch

poplar strips, the joint was a 45 ° angle so the mitres were each

22.5 °. |

|

Here the edge bands are glued up. |

|

After glue up the top slab was

sanded and prepared for paint. |

|

Then the carcase cabinets were constructed with brads and glue and screws as needed. The image shows the carcase cabinets during clamp time.

|

|

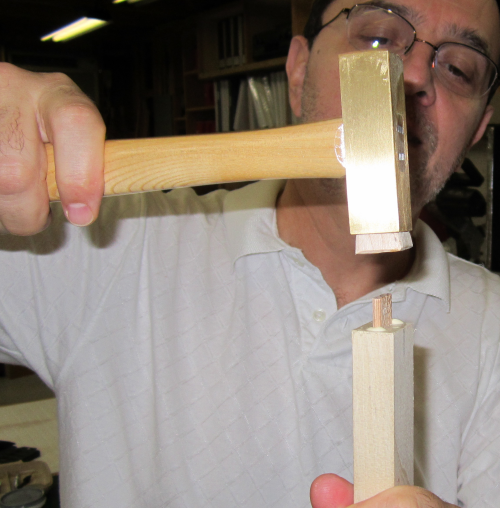

The cabinet face frames were made with poplar and were joined with mortise and tenons using the Festool Domino. Here Boba is tapping in a Domino tenon.

|

|

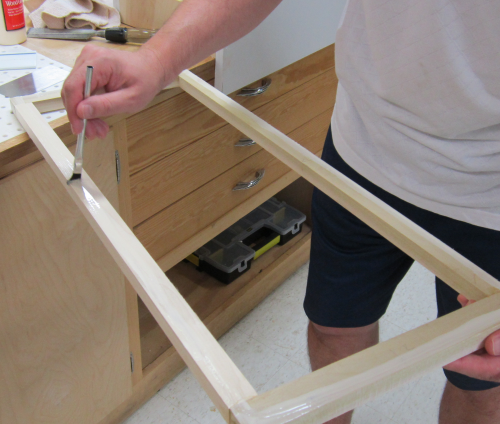

Cabinet frame glue up.

|

|

Preparing to glue the frames onto the cabinets. |

|

Cabinet doors were also made of birch panels

with poplar edging. Here the door is secured to cabinet frame. |

|

After attaching pulls, the two cabinets are ready to be painted.

|

|

A quick dry fit to see how the geometry played out... |

|

Ready to transport in sections for painting and then final construction. |

|

Dry fit...after painting. The door on the right end was a defining point in the geometry.

|

|

Test fit with cabinet doors open... |

|

Test fit 2...unit looks good painted... final phase will be be to attach a rear stiffener to stabilize the unit to finish the cabinet structures by attaching rear panels on the cabinet abd installing glide pads on the bottom. |

|