When the shop was built the design included a central dust collection system. Financial issues caused a delay in that installation. The dream system was a Oneida Gorilla 3 hp. cyclonic with

ductwork to every machine. It appeared to a patchwork quilt solution but it ended up being very effective. The dust situation was also radically improved by migrating to hand tools for many task.

|

|

|

|

I decided to begin with some simple but effective dust reduction steps. I began to use an Airshield Pro system whenever I am producing large amounts of airborne dust particles (eg. routing, sanding).

This unit is battery operated to provide constant fresh air flow across the face to prevent shield fogging. Unit includes an eye protection shield and a

head protection shell in addition to protection for airborne dust. |

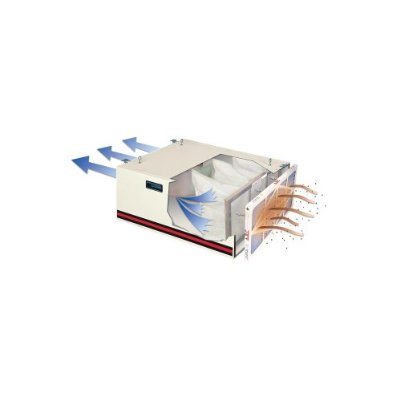

To aid in the reduction of airborne dust particles, I installed a Jet Air Filtration System.

|

The AFS 1000 produces 1000cfm and filters the air in my shop in around 10 minutes. The three speed unit has a remote control and a time delay will turn off unit after a big job.

|

After researching the best location, I installed the AFS 1000 about 1/3 of the way along the south wall. This is opposite the Air Conditioner air flow.

|

I liked the AFS 1000 so much, that when I had the opportunity, I purchased a used unit from my brother. This device was hung on the north wall to provide maximum circulation to take air borne dust particles from the machines to the filtration devices.

|

I purchased an Oneida portable cyclonic to

use with one machine at a time. The Mini Gorilla has

a five inch port. Migration The Mini Gorilla hose and port system can be

configured 3. Planer 4. Base of the chop saw station |

|

|

The Mini Gorilla lived in the north east

corner of the shop. |

| It migrated into the corner to create more room

|

And reached a final destination outside.

|

I also have a Jet canister model, mobile, 1 1/2 hp dust collection unit.

|

It was purchased used. It lived in the south west quadrant of the shop for a year but was moved to reduce noise in the shop and save some space.

|

The Dust Dog pulls dust from: 2. router table 3. band saw 4. jointer 5..Cleans the shop via the Dust Right System

|

The Dust Dog now has a home behind the shop.

|

A Rigid 12 gallon wet/dry unit

is the large shop vac. It has a 2.5 inch hose. |

|

|

A Festool CT 22 is the medium size (5.3) shop vacuum. It is part of the Festool system, specifically designed to work with the MFT3 workstation and the QT 75 EQ plunge saw. The connector is 1 1/16 inches. Fits all Festool products. |

The CT22 with Oneida cyclonic, and boom arm at the MFT 3 workstation.

|

|

Festool CT 26 under bench. This unit pulls the chop saw blade cover. It is also the DC that goes to the garage when the cutting table is set up there. |

|

A Stinger is the small (2 gallons) shop vac. Has a 1 1/4 hose It is used for assorted clean up duties. It provides dust collection for the Kreg jig. |

|

Individual Work Stations Dust Collection 3. band saw 4. planer 5. router table 6. table saw 7. jointer

|

|