|

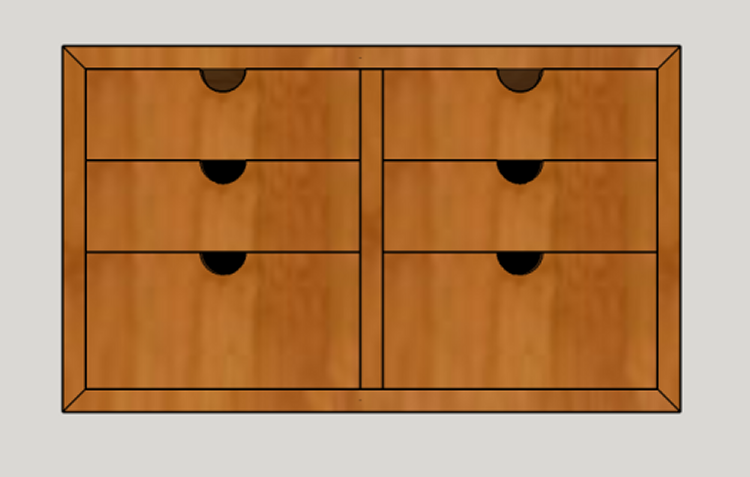

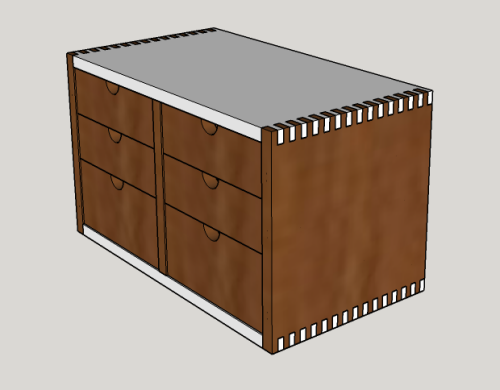

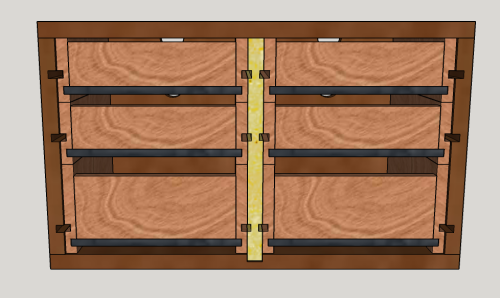

I need a storage cabinet for

external drives and USB flash drives at my computer

workstation.

There will be two 3 x 6

drawers side by side at the bottom.

The top will have four 2 x 6

drawers.

Configuration shown below.

Final Milling, Carcase Assembly

|

|

|

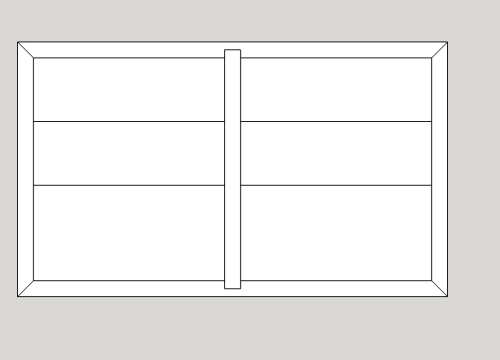

A Sketchup model of the basic layout. Most material will be 1/2 inch thick.

|

|

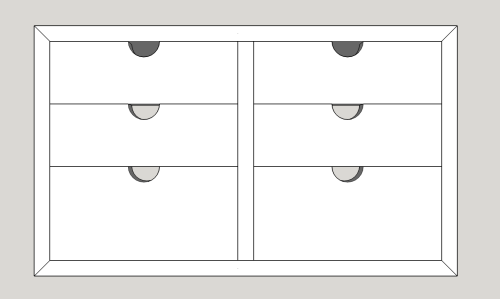

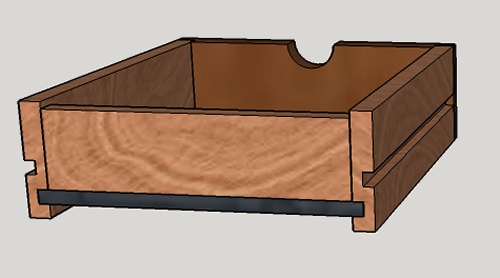

| This view shows thumb holes in

the drawers for easy pulls. These are 1/2" radius holes...thus 1 inch wide, 1/2" tall. The center piece shown here fits into a stopped dado and instead of a through dado as shown above. |

|

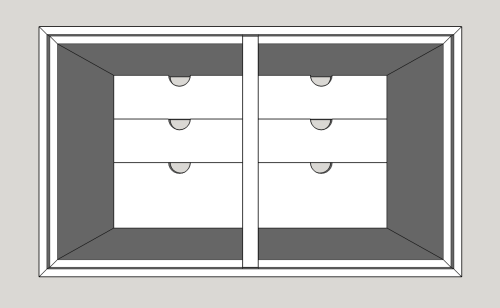

| This is view of the rear of the

box...there is a .125 inch rabbet around the interior edge of

the carcase to let in the rabbet to accommodate a rear panel of

1/8" hard board. |

|

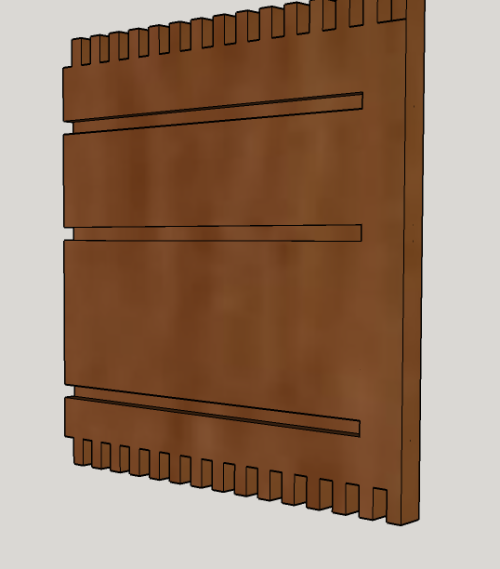

| Original plan was for miter

joints...changed design to use box joints...top and bottom

panels are white here for differentiation purposes... |

|

|

|

|

|

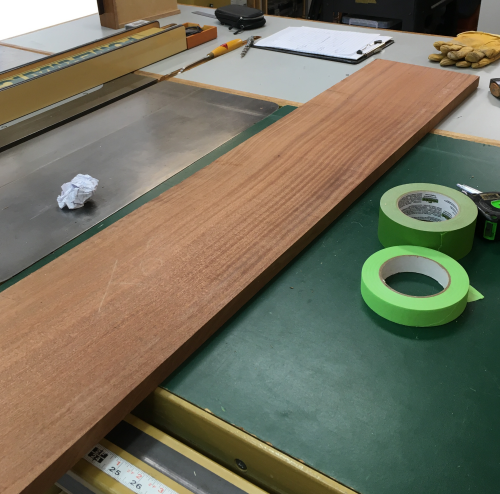

The cabinet wood in this project will be

African mahogany purchased down in Star. This plank was pulled out of deep storage in shop attic. Should be truly dry.

|

|

| African mahogany, also called

khaya, acajou d"Afrique. Scientific: Khaya A. ivorensis Color and appearance: Heartwood ranges from pale pink to a deeper reddish brown, sometimes with streaks of medium to dark reddish brown. Colors darken with age. Quartersawn surfaces exhibit a ribbon-stripe appearance. Info from wood-database.com |

|

| This plank started as 4/4

lumber...we surfaced both sides when we got it to look at the

grain...it is now about 7/8 inches thick The blank is 60 inches long and 5 feet long...about 9.25 inches wide. After layout the blank was ripped to 7.75 inches to

allow access at jointer. |

|

| The sides of the drawers and the

muntin wall will be red oak. Quartersawn blanks...these two

blanks were ~1 3/8 inch thick...after jointing a face and an

edge they will be milled. Need 4 blanks @ 3" wide, 7" long, 3/8" thick Need 8 blanks @ 2" wide, 7" long, 3/8" thick |

|

| Resawn at bandsaw...5/8 inch... |  |

| Blanks were jointed as needed and then surface planed...down to ~1/2 inch. |  |

| Blanks are now ready to be drum sanded to 3/8" thickness. |  |

|

This white oak blank was not

tall enough to be the center muntin panel...chopped it,

jointed edges and put in Dominoes.

|

|

| Glued the blank together...drum

sanded...blank ready to be milled. |

|

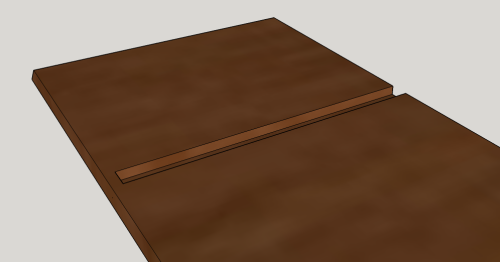

| The top and the bottom panels will have a stopped groove to accept the notched top and bottom of the center muntin. |  |

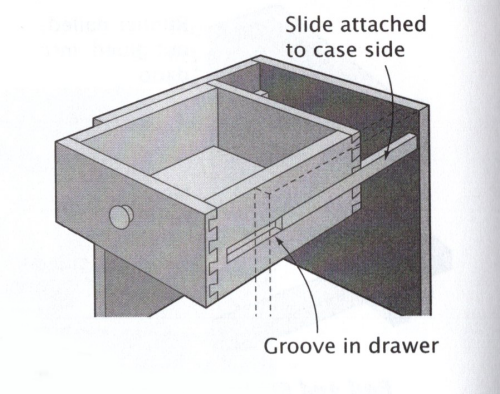

| The drawer slides will be

attached to interior sides of the case. |

|

| The grooves in the side panels must be stopped grooves. |  |

| The center panel will be

secondary wood with a 1/2 inch muntin attached to the front

edge...so the grooves in this panel can be through dadoes |

|

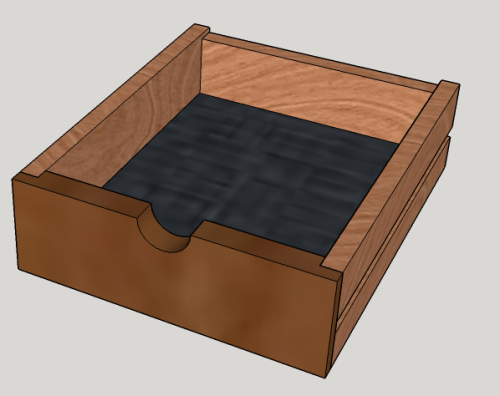

| The inner drawer faces will have

a 1/4 inch groove by 3/16 inch deep to let in the MDF bottoms.. These grooves can be through grooves. |

|

| The drawer joints...the front

will have 1/4 x 3/8 rabbets to let in the drawer sides... |

|

| The rear view of the carcase with

drawers in...the rear panel of the carcase will be 1/8

inch thick hardboard. |

|

|

|

|

|

|

|

| Then they were finished sanding

at the drum sander. |

|

| Blank selections were made

according to grain alignments. |

|

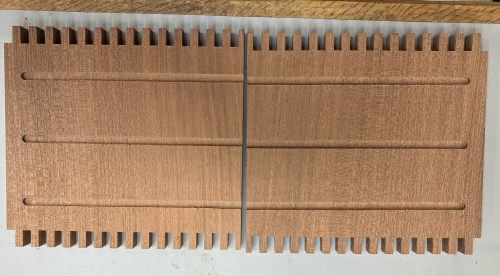

| Top, bottom and sides were finger

joint milled on P66 with jig and the Infinity .25 blade. |

|

| We learned a lesson regarding

finger alignments... |

|

| To make the dadoes we would use

small router for the 1/4 inch slots in the sides and muntin. We decided to mark the center line of the bit...used half rule. |

|

| With a small angle file, we etch

marked the plastic guide for the center. |

|

| Marked in red | |

| The top and bottom blanks need a

1/2 inch dado to accept the muntin. Used MFT/UJK setup to use Festool router. |

|

| Festool router setup...we should

have used the longer edge of the router... |

|

| Stopped dado was controlled

visually. |

|

| Stopped dado cleaned up and

squared with chisel. |

|

| The box carcase was dry fit and

the drawer dadoes were center using 1-2-3 blocks. |

|

| Then the knife marks were

extended... |

|

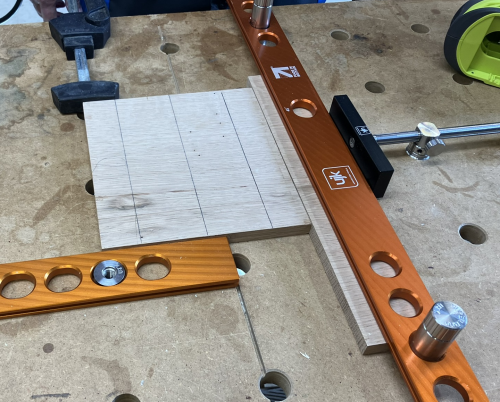

| MFT/UJK setup for the Ryobi

router. |

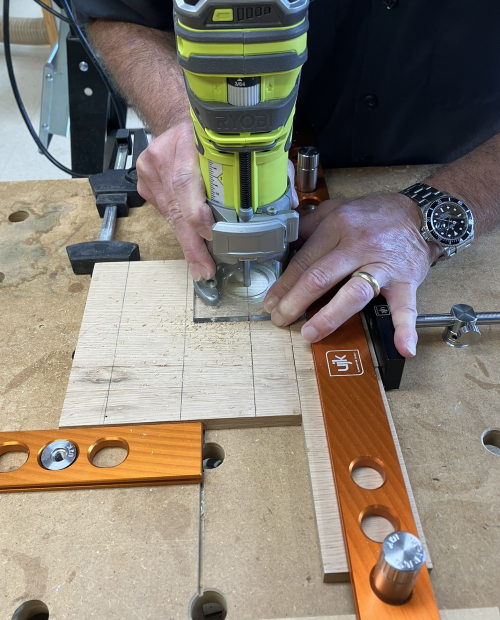

|

| Router in use... |

|

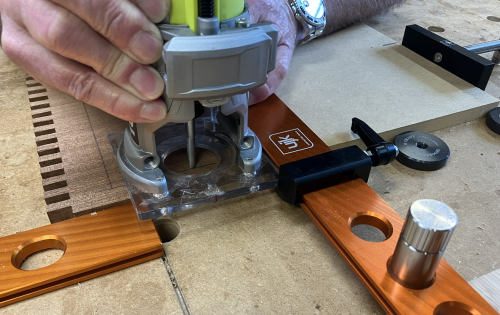

| For these stopped grooves we used

a UJK stop...worked great. |

|

| Stopped dado... |

|

| Alignment check for the

grooves...all good except top left off a skosh. |

|

|

Milling

and Assembly of Drawers

|

|

| Hardware selection...Horton H-42,

3/8 inch, dark antique, with wood screws (3/8 inch) |

|

|

|

|

|

|

|

|

|

|