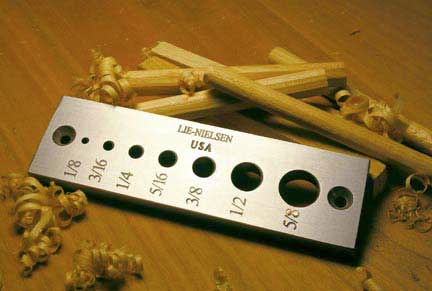

I want to be able to produce shop made dowel pins out of any wood that I wish. Additionally, I want to be able to make my pins with good grain orientation. I purchased a dowel plate from Lie-Nielsen.

|

|

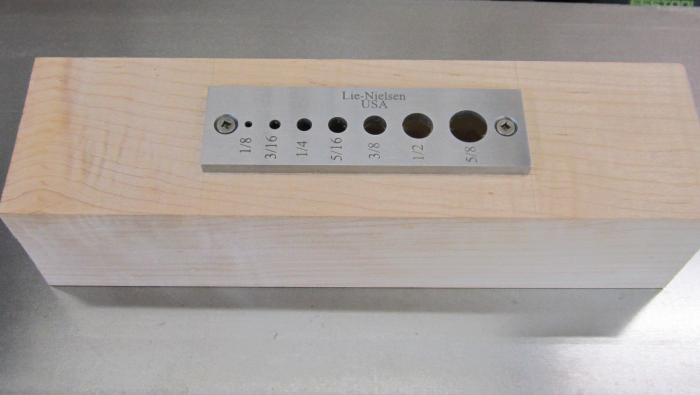

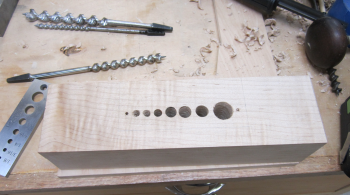

To make it easy to pound stock through the plate I decided to attach it to a block of hard maple. I milled a piece down from some 12/4 hard maple my brother Tom recently brought me from Virginia. |

|

| I laid out the plate outline and dowel holes onto the block leaving ample room at each end to be able to clamp the block down easily. |

|

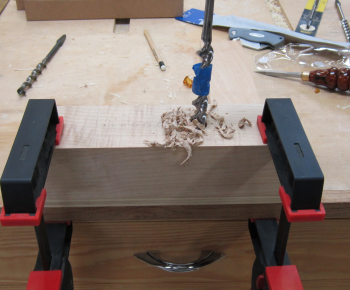

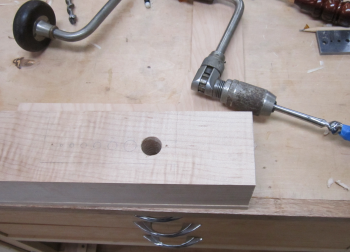

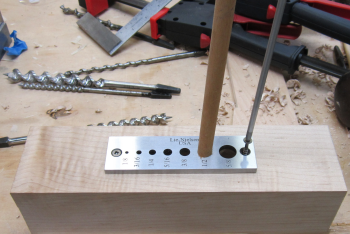

I decided to use a recently refurbished Stanley brace with some recycled old auger bits and a few "new old stock" Jennings Pattern bits that I just found at Tools for Working Wood. Here I am using a 3/4 Jennings. The largest hole on the plate is 5/8 so I was creating a slightly oversized hole for easy dowel management. |

|

Here is the first hole...I put tape on the bit as a depth gauge and had a sacrificial board under the maple to minimize blow out. I struggled a bit to keep the bit straight. It was also difficult to get leverage onto the brace at the bench height.

|

|

So I got up on a stool...leverage was better

and I used a square to help me stay lined up...I am going to need lots

of practice before I master this method. |

|

I did all of the holes oversized except

the 1/2 hole. I did not have an auger bit that was appropriate. |

|

So when I screwed down the plate I made

sure that the 1/2 inch lined up perfectly before I tightend the unit

down. |

|

The finished product. Should be ready for some serious pounding.

|

|