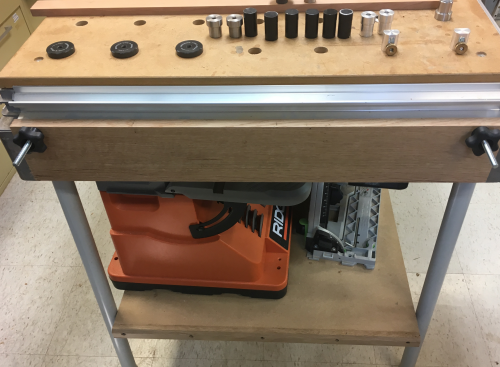

Needed a better way to store my MFT3 dogs...they have been in a refrigerator ice container that was clumsy and the plastic was failing...I have a number of different types of dogs... 4 BT&C Spots, 6 Qwas dogs, 2 short and 2 tall Parf dogs, |

|

Recommended for a solid project: "Any dense hardwood and it should be quartersawn stock." I pulled a 4/4 white oak boards from the attic...quartersawn with flakes on the surface...plus pretty good vertical end grain. |

|

Had a strip cutoff of 1/2 inch cherry |

|

Milled the oak to 3/4 inch thickness...jointed and planed...ripped to 4 inches and chopped it to match the width of the end of the MFT 3 table... |

|

Drilled a couple of 5/8 inch holes out the ends the oak base rail...put in a couple of handles on the 5/8 - 18 bolts... |

|

these bolts are too long...have some appropriate length T-bolts coming... (2 1/2 inch). |

|

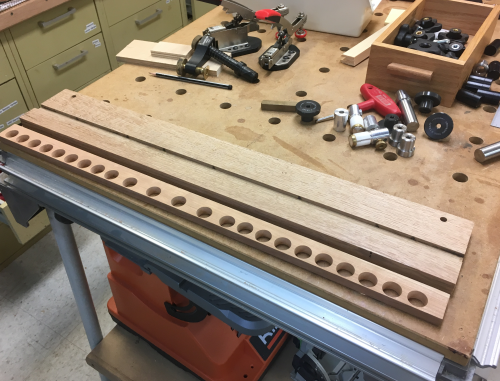

Laid the cherry out for 20 mm holes to be centered at 25 mm between most of the dogs...with 40 millimeter centers for the larger dogs. The oak got a 1/2 dado for the cherry ledge to slip into. |

|

Dry fit of cherry ledge and all of the dogs... |

|

Decided to add some kind of way to hold up the Anderson MFT3 layout square. |

|

Edges were planed.....then edges were chamfered...surfaces sanded...glue up was with hid glue. |

|

Glue up...though I tried to be gentle on the cherry, there was a minor blow up towards the thin front area...glued it up and blew it off... |

|

Put on a coat of wiping varnish...shop brew...used the bottom of a plastic tub with the varnish thickening...seemed to rub in ok... |

|

Test fit for all of the dogs... |

|

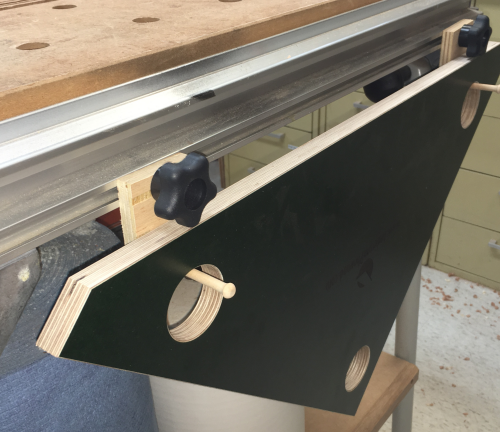

New 1 1/2 inch T-bolts installed...handles fit much nicer... |

|

After hanging the dog rack, I decided that I did not want the layout square attached to it...I opted to create some independent hangers that would be more flexible. |

|

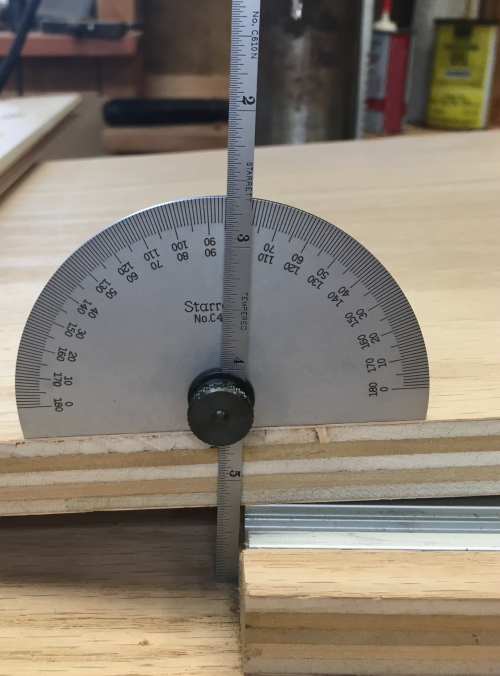

Dowell holes needed to be on an angle...got out the drill press angle jig...I had never measured the lowest angle possible...angle gauge says ~4°... |

|

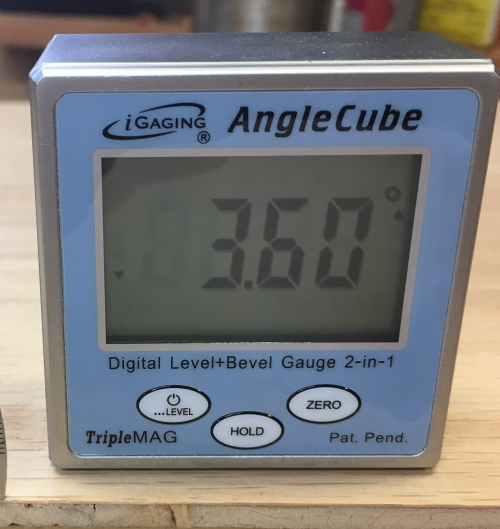

...confirmed this using Angle Cube. |

|

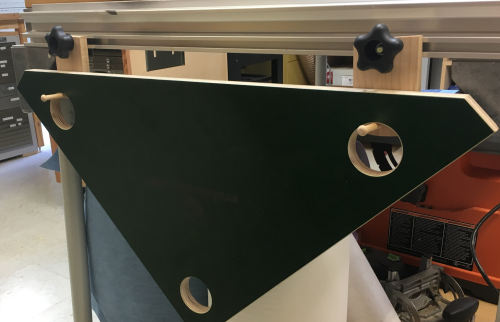

After testing with the plywood mock-ups...I decided to make the hangers more robust and a bit longer...because the knobs hit the top edge of the square... |

|

So, I switched to a thicker piece of maple and worked the edges with rasps... |

|

Hanging on the end of the MFT but will try out the backside as well... |

|