Dust Collection Band Saw |

|

| The new Powermatic bandsaw is

located to the right of the door on the southwest wall.

|

|

The Jet unit is operated by a remote control

switch.

|

|

The center line here is the path to the band saw. |

|

The front and center lines continue westward. |

|

At the end of the main bench the middle

line goes down to the floor. |

|

| For the junction at the floor we used a Rockler Dust Right "though

the wall" setup with two flanges and a tube that goes through the

wall (or in this case the floor). |

|

The tube had to be cut down on the bandsaw

to make it the proper length for the two flanges to sit flush. |

|

Aftrer the tube was cut down so that after

insertion into the two flanges there was a 1 1/8 gap. This is the thickenss

of the floor substrate plus the tile. |

|

A hole was drilled using a four inch hole

saw. |

|

After the unit passes the floor, the under-the-shop-flange is secured and the hose is connected. |

|

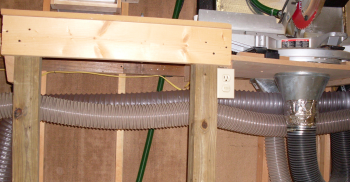

The line then crosses underneath the shop. It is contained in the space between the florr joists and floats in space held only by strapping material to prevent sagging.

|

|

The line then re-enters the shop and a hose is connected to the flange on the floor by the southwest wall. A new 220v electrical line was run at the same time and the bandsaw was rewired to run on 220v. |

|

The final phase of this long and winding road is connection to the four inch cast iron port on the rear of the Powermatic.

This fitting rotates and has a 2 1/2 tee that is connected to a flex hose. |

|

A rigid flex hose comes off of the 2 1/2

flex and can be positioned to pull dust at the point of the cut. |

|