Trying to create a prototype of a sliding top box similar to a pencil box...I hope to then mass produce some as gifts. The primary purpose of this sled is to provide accurate and easily repeatable 45 degree cutoff. No real preplanning...we just threw together a CTD sled...

|

|

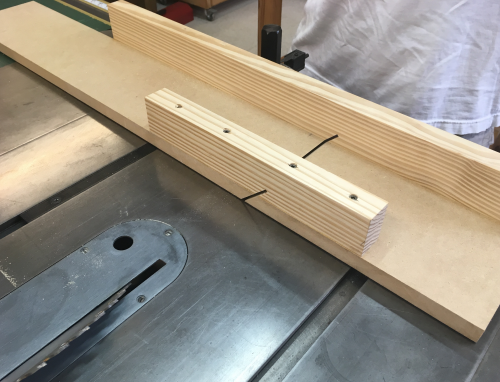

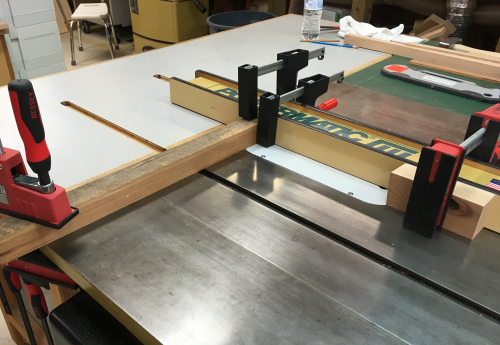

We threw together

some scraps to make the |

|

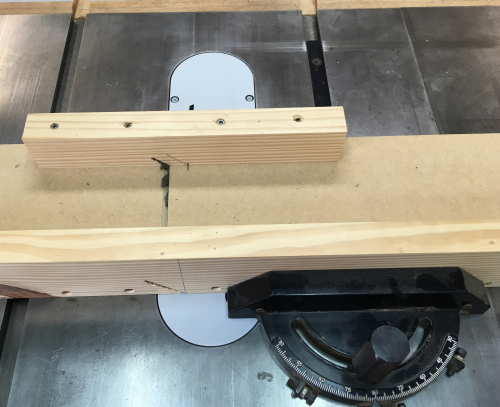

Attached the fence to a miter

gauge... |

|

...used #8 1-3/4 inch SD screws...ready

for tune up and a test run... |

|

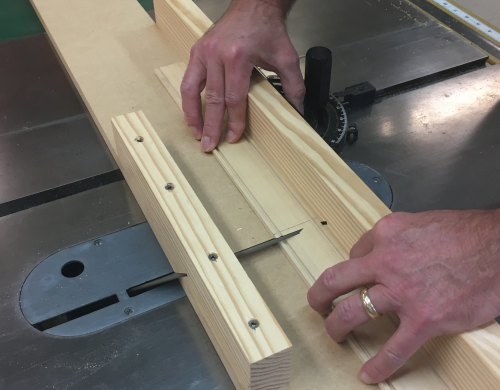

...mitre guage was squared to

blade, blade angle set to 45°...this angle is really tight in the

throat of the P66 insert...will make another. |

|

initial cut made in sled |

|

sled ready to work |

|

finished product ready for first

run...and long blank, already grooved is mitre cut fat on one end... |

|

and then flipped with stop block

to mitre the short ends |

|

...and then the long sides. |

|

Dry fit...taped as needed... |

|

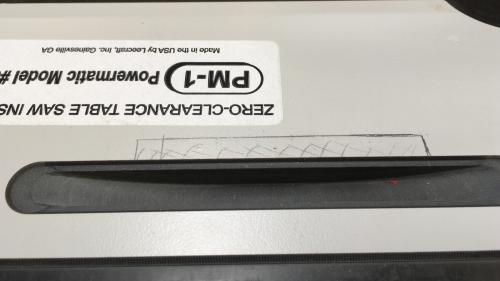

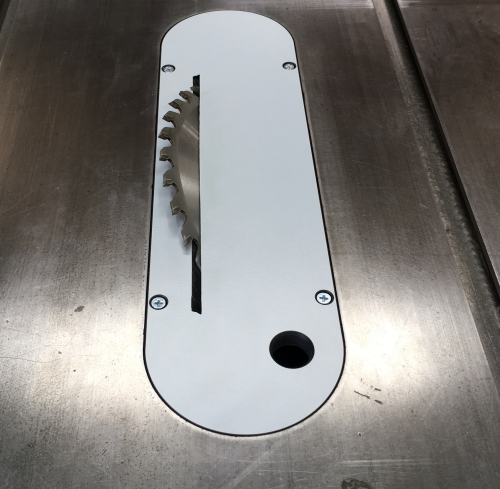

To solve the issure above, the tight fit of the OED insert at 45° I bought a Leecraft PM-1 zero clearance blank insert.... |

|

Because the P-66 trunion will not lower far enough for the blade tips to have clearance beneath the insert, the PM-1 has a slot cut into the under side to provide clearance...however, with the blade at 45° the insert will not fit properly over the cutting edges. The penciled-in area shows the contact points...this area will have to be removed...so that the insert may lay flat. |

|

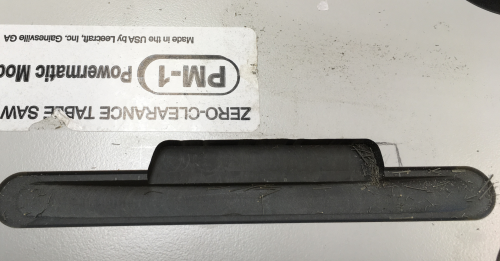

I set up on MFT3, secured the blank, used a router with a straight 1/4 bit to remove material (to a depth of 1/4"). |

|

On a second run, elongated the cutout by removing stock to a lesser depth...about 3/16"... |

|

The insert was then secured in the P66... |

|

...and the blade was run up at 45°...till it broke through... |

|

...then extended to ~1.5" (.75 inch to get through sled and .75 inch for the mitre cuts. |

|

...in the sled. |

|