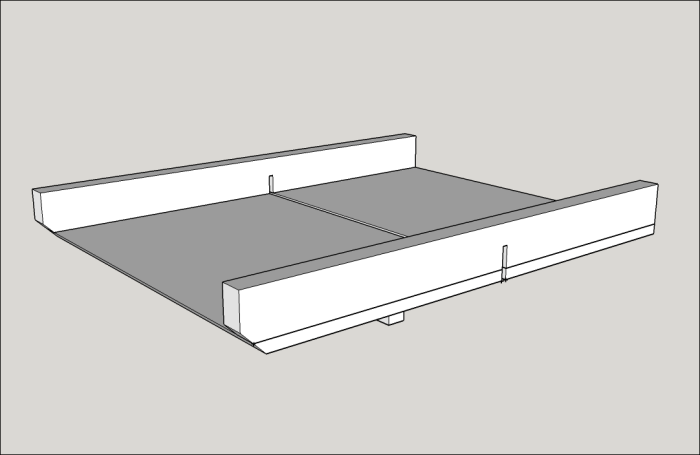

I designed a small and efficient dual purpose cross cut sled to meet my needs...my regular crosscut sled works great but it is large and as I age it is becoming more difficult to use. The main purpose of this smaller sled to to provide crosscut capability for use with my Infinity flat top 1/4 inch blade.

A secondary purpose is to provide 45 degree cutoff.

|

|

I liked the sled that Matt Kenney (Fine Woodworking) had shown in his "How to make a 'Super-Precise' crosscut sled"...his build went rather quickly...see article here. |

|

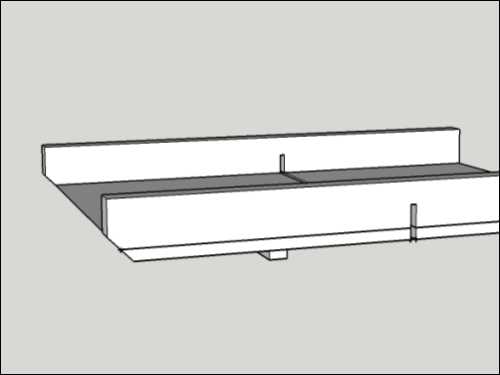

I built my design around a single Incra 18 mitre slide. The runner has adustable set screws to reduce slop in the mitre slot.

|

|

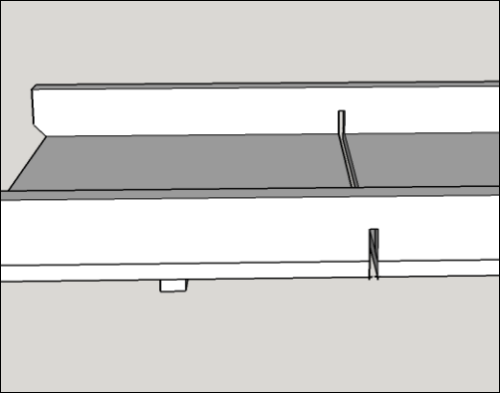

The runner will be attached to a 24 x 18 base of 1/2 inch Baltic birch. With the jig in the left mitre slot on the P66 the sled will be used to crosscut with the 1/4 inch kerf of the Infinity blade. |

|

When the jig is in the right mitre slot the left edge of the jig will provide a 45 degree cut using a combo-cut Tenryu blade. Cut offs will fall to the top of the P66 and should not get caught under the blade.

|

|

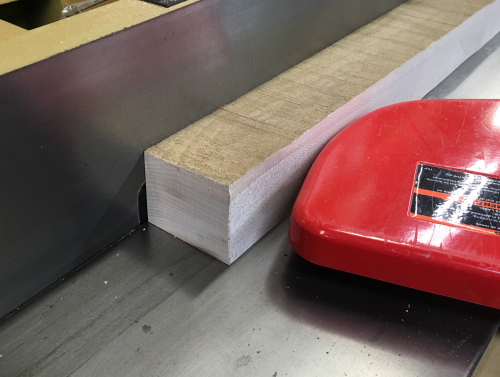

Gathering of wood...had a 48 inch cutoff of maple...ran a face and an edge through the jointer...this slab will make the bridge/fence boards. |

|

Fences prepped... |

|

Laid out installation lines and hole marks to mount the runner on the bottom of the jig. |

|

Small holes were drilled from the bottom, then the 4 screw holes were countsunk from the top... |

|

The 2 holes that are not for screws allow a 3/32 hex to tight adjust the the runner to fit the mitre slot... |

|

The front fence was then attached to the jig base...screws #8 x 1 3/4 were counter sunk from the bottom into the maple fence. The front edge does not have to be square, it only serves to hold the base together (as a bridge) when the base is cut by the 1/4 blade...the rear fence must be square...we secured the right end as a pivot point...then cut the base nearly to the rear fence... |

|

We then used the sawn 1/4 inch kerf as the alignment lines to square the rear fence...we got it close with traditional squares... |

|

But the best squaring method was using flat squares...the Veritas 6 inch and a drafting square with a 1/4 sheet of MDF in the kerf. We did not chamfer the bottom of the rear fence for dust relief...we opted to not chamfer in order that the squaring go better...we will have to brush clean more often. |

|

Once squared, clamped the rear fence and then drilled and screwed the other 5 connections... |

|

Sled is ready...the mitered side edge is put on hold. |

|

Never got around to using the mitre sled cutoff...but needed to crosscut some rails at 4.5 degrees on the A&C chair project. Used the sled for this task. |

|

|

|

|