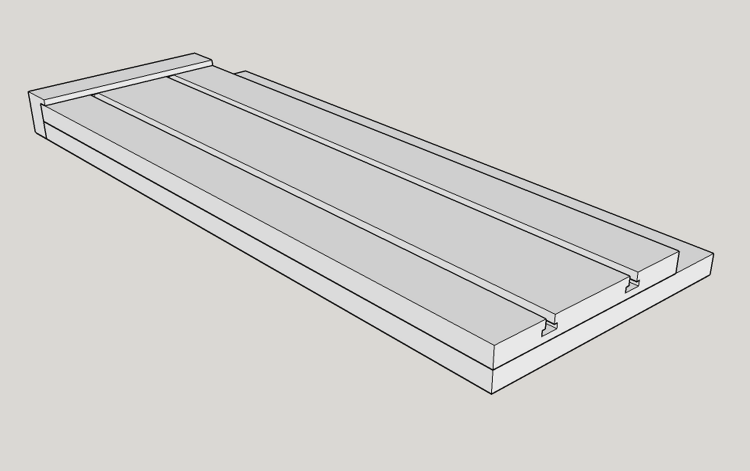

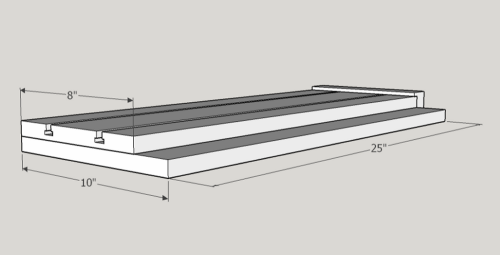

I purchased a Veritas Combination Plane. When using the plane's fence, due to the height of the fence, it was difficult to hold a work piece coplanar with the front of the workbench...the dog holes were too far in from the workbench edge to allow a stop to hold well. The fence is 1 1/4 inches tall so a flat 3/4" thick piece of stock would not allow the fence enough room. The fence needs to overhang the front edge. This planing sled jig will enable the secure holding of a work piece...and the sled can be located so that the workpiece and the plane fence overhang the front of the bench. Additionally, the thickness of jig (1.5 inches) will allow the plane to be used elsewhere on the bench.

|

|

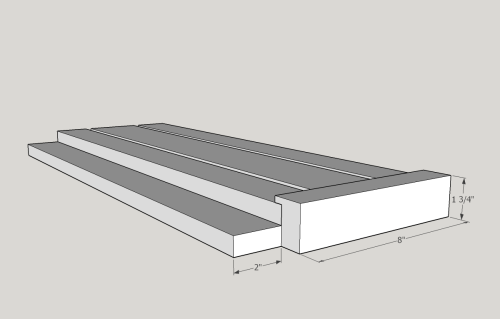

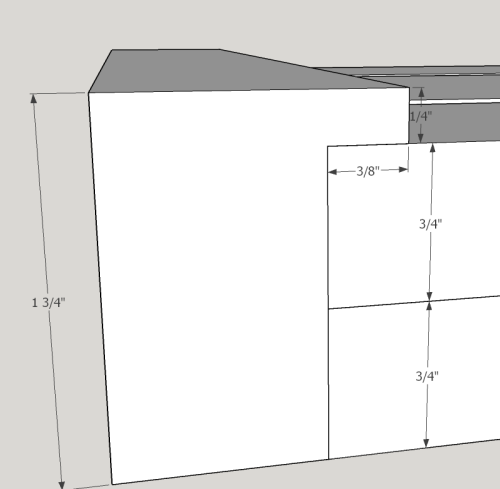

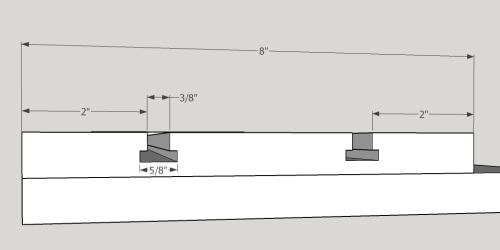

End view of jig... |

|

Profile of the maple end cap fence... |

|

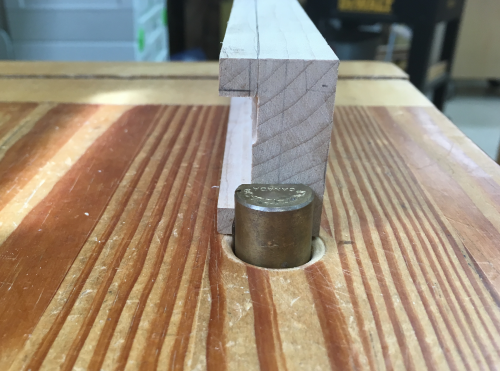

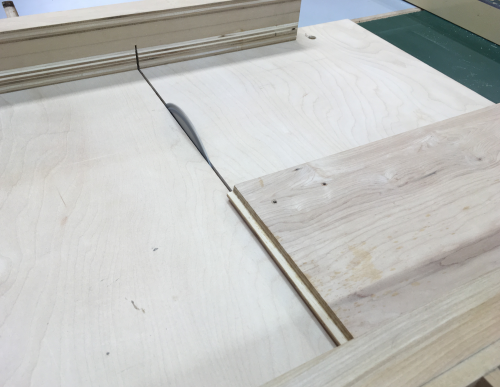

To create the maple end cap...I hogged out the center of the rebate at the router table...left two lips...the fence lip and a balance lip that has to be removed...did this with the BA carcase saw. |

|

Then I removed any irregularites with a paring chisel... |

|

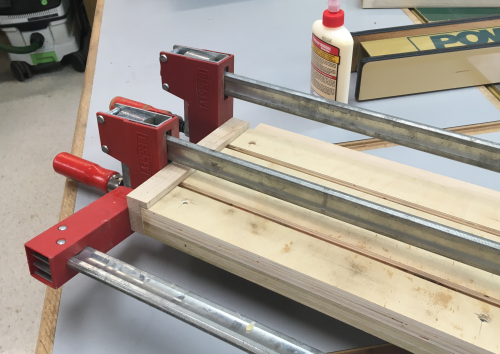

The sled was made with two pieces of 3/4 inch baltic birch plywood...reclaimed from a couple of cabinet doors... |

|

The maple end cap fence was glued onto the end of the sled... |

|

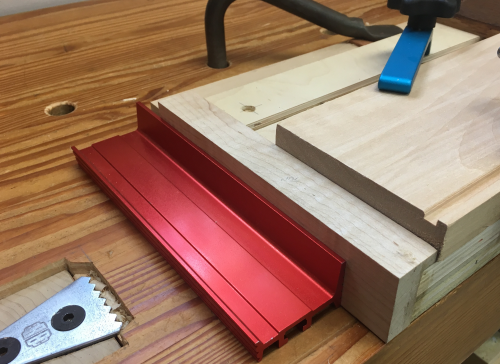

End view of the top sled board with the T-slots... |

|

Routed the 3/8 inch slot with a up/down cut spiral bit... |

|

...then, without moving the fence...switched to the t-slot bit which put a 5/8 inch wide slot...

|

|

...t-slots. |

|

The upper sled board was screwed to the lower sled board...the lower board is 2 inches wider than the top and the back edge of the jig will be used as a securement point with holdfasts... |

|

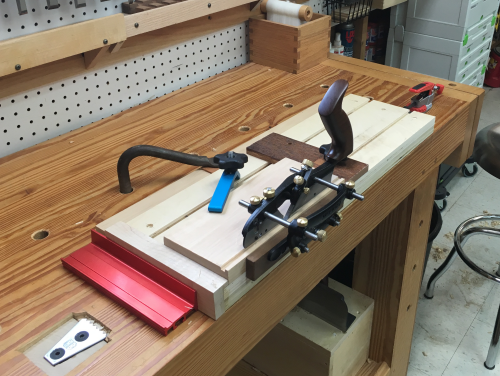

Sled ready for clamping system... |

|

In Use |

|

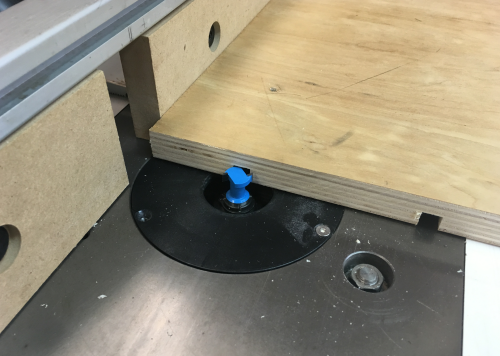

Any of a number of bench stops would hold the sled at the sled stop end cap...bench dogs, the Benchcrafted planing stop or the one used here a bench dog fence (Armor Tools). |

|

The tail end of the sled is held by an Armor Tools self-adjusting in-line dog clamp... |

|

The back lip of the sled can be secured with bench hold downs... |

|

The workpiece board rests against the maple lip on the front of the sled...in some instances the hold down may be run down the T slot and help secure the workpiece. |

|

The tail end of the workpiece is held in place by a sliding end restraining unit which is locked with 5/16 T bolts and knobs. |

|

After competion of sled and using it, I decided I would need an edge restraining unit as well...so I drilled an opening near the fence...this allows clamping unit to be installed without removing the end restraint unit. |

|

The full sled... |

|