|

My friend TJ, a quadriplegic,

needed a modification to make it easier to use his sip and

puff assistive devices.

|

|

|

Original Design...

TJ was using a QuadJoy and Dragon Naturally

Speaking for computer access.

|

|

|

The facility requires nurse

call access.

This image shows QuadJoy mount

and the separate nurse call.

|

|

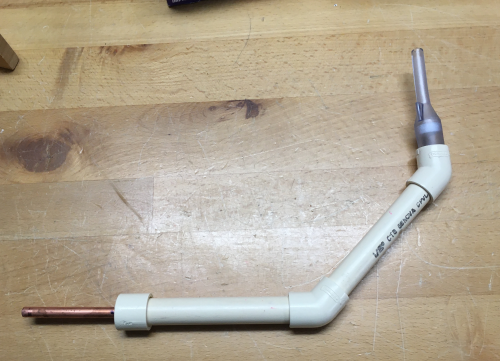

| Staff at the facility were having

difficulty adjusting the two sip and puffs...so, my BioMed

buddy, Greg, had come up with this scheme years ago...he used

CPVC pipe with copper pipe inside it to create an

alternative location for the nurse call (BreathCall)...the unit

was actually attached to the side of the QuadJoy. |

|

Later, we needed a third sip and puff for ECU access. A second BreathCall was added to the

QuadJoy.

This put all three sip and puff actuators

in proximity to each other.

|

|

| In use... |

|

Over time, the QuadJoy reached the end of its lifetime...the facility provided a QuadJoy 3...and they wanted the nurse call to be separated in the new configuration. |

|

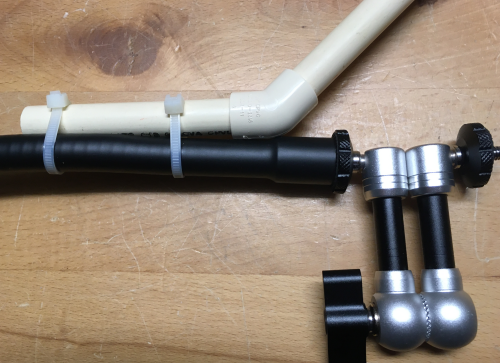

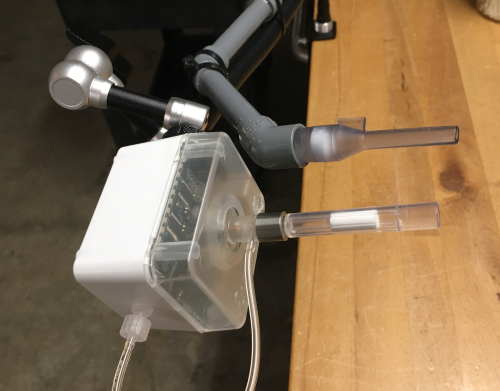

We secured a new clamping arm for the QuadJoy 3 |

|

|

|

|

|

The geometry of the new mod had to be

determined at home in the garage...used an old QuadJoy for

assessing alignment in 3D world. |

|

| Had to guesstimate the reach of the QuadJoy straw... |  |

| New clamp system, with

articulating joint at the end of the arm, provides a good bit of

latitude...this was secured from quad.life. |

|

| Dry fit ... |

|

|

|

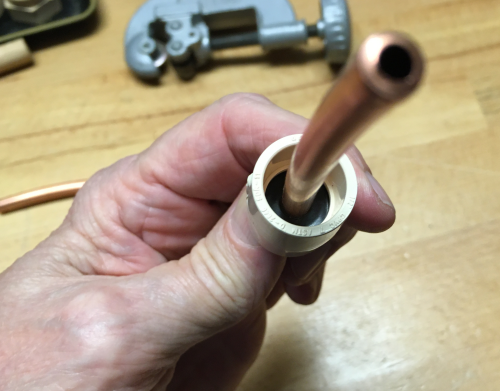

|

The copper pipe is the breath way...the CPVC is providing support and protection. The sip and puff end of the copper pipe needed to be secured and centered in the CPVC. |

|

|

Found the perfect washer in Reece's Pieces bin. |

|

| The washer was epoxied into a 45°

fitting. |

|

| The sip and puff tube from a

BreathCall is a perfect fit into the fitting. |

|

|

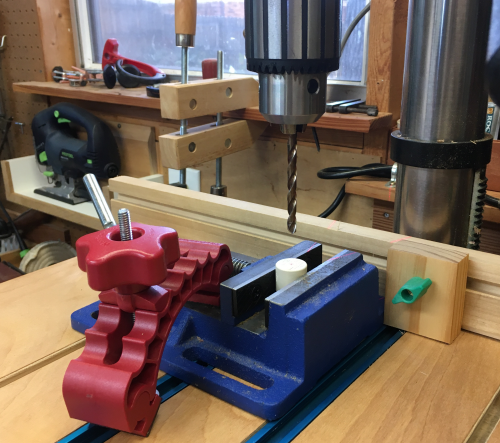

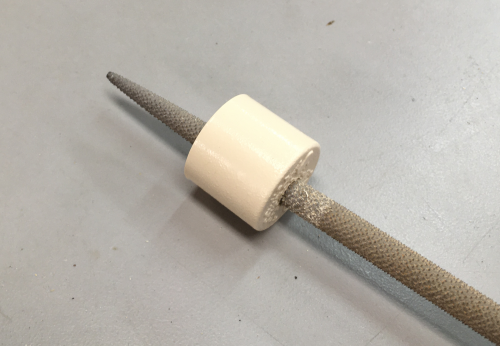

End Cap...needed a hole to keep pipe

centered.

|

|

| Used rat tail rasp to perfect

sizing... |

|

| End view of mod...tubing from the

switch device will fit over the copper tube. The copper pipe is slightly larger than the original design. |

|

| The final dry fit...CPVC will be

glued with appropriate solvent...the copper pipe and washer

assemblies will be glued with epoxy. |

|

| Spray painted the outer

pipe...the highest December temperature ever and high humidity

caused a drying issue...had to keep a fan on it... |

|

| Wire tied the mod to the arm... |

|

| Ready for installation... |

|

|

|

|