|

Frame and Panel Tray |

|

|

|

|

|

|

|

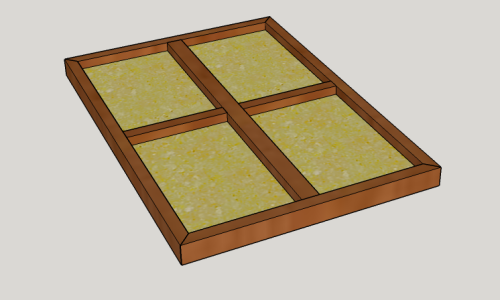

| We decided to aim for a frame and panel tray. |  |

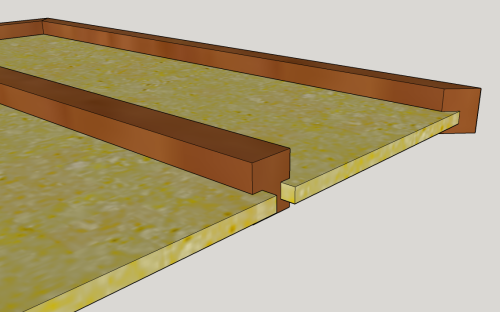

| The two panel sections of

maple will sit in a frame and center divider assembly out of

Honduran mahogany. The SketchUp colors are not totally realistic...but are representative of the real wood. |

|

| Each maple panel is 1/4 inch

thick, 5 inches wide and 15 inches long. The frame will be ~15.5 inches long and ~11 inches wide. The two smaller frame pieces will rest on the panel but will not extend to underside. |

|

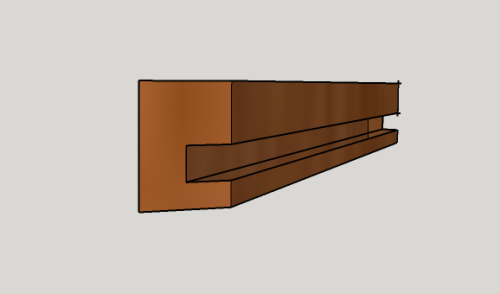

The frame sides will have a 1/4 inch x 1/4 inch dado put in, 3/16 from the bottom edge. The corner joints of the frame will be mitered. |

|

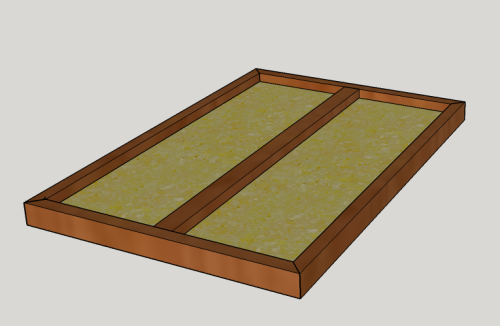

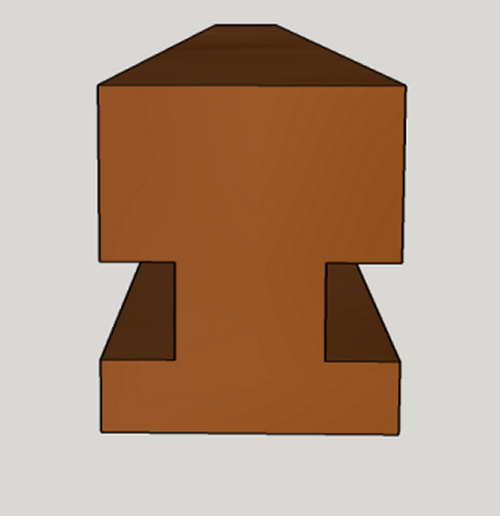

| The center frame piece will

be thicker (.75 rather than .5 inches). This is to accommodate a 3/16 inch deep dado on both sides...this frame piece will be called the iBar frame member. |

|

| The iBar will connect with

the end frame in a butt joint...will probably use a small domino

mortise and floating tenon. |

|

| Used the Infinity 1/4 inch

flat top blade on the P66 and created 1/4 x 1/4 da |

|

|

|

|

| The maple panels were pre-milled

to .25 inch thick...width is a skosh over 5 inches...panels were

chopped to 15 inches. These panels are highly figured birdseye maple. |

|

| The Honduran mahogany is recycled

wall paneling. The lower piece here is a cutoff of the sculpted edge of the paneling. The upper piece has been planed and sawn to thickness. |

|

|

Used an Infinity 1/4 inch kerf

blade with flat tips to create the grooves...1/4 x 1/4 on the

side frames...1/4 x 3/16 on both sides of the iBar center

frame.

|

|

|

|

|

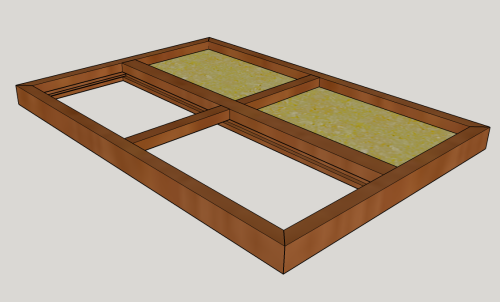

| Dry fit assembly and

milling...using a cutoff in the center to make alignment at the

corners easier. |

|

| Dry fit of all milled

pieces...except the center dividers which will be put in after

assembly. |

|

| All sides were planed as

needed...LV small smoother... |

|

|

|

|

| Wax |

|

| Glue up |

|

| Final finish |

|

| |

|